How to Choose the Best CNC Milling Machine for Your Needs?

Choosing the right CNC milling machine can be daunting. These machines vary widely in features and capabilities. Understanding your specific needs is vital.

Consider your project's materials and complexity. A high-quality CNC milling machine may be necessary for intricate designs. Simpler tasks might only require a basic model. Research different brands and models diligently. Some machines have user-friendly software, while others may not.

Take your budget into account. Higher prices often correlate with better performance. However, not all expensive options are suited for every project. It's essential to align your financial resources with your requirements. Reflect on your future projects as well. Will you expand your capabilities? Finding a balance between features, price, and your requirements is key to a successful purchase.

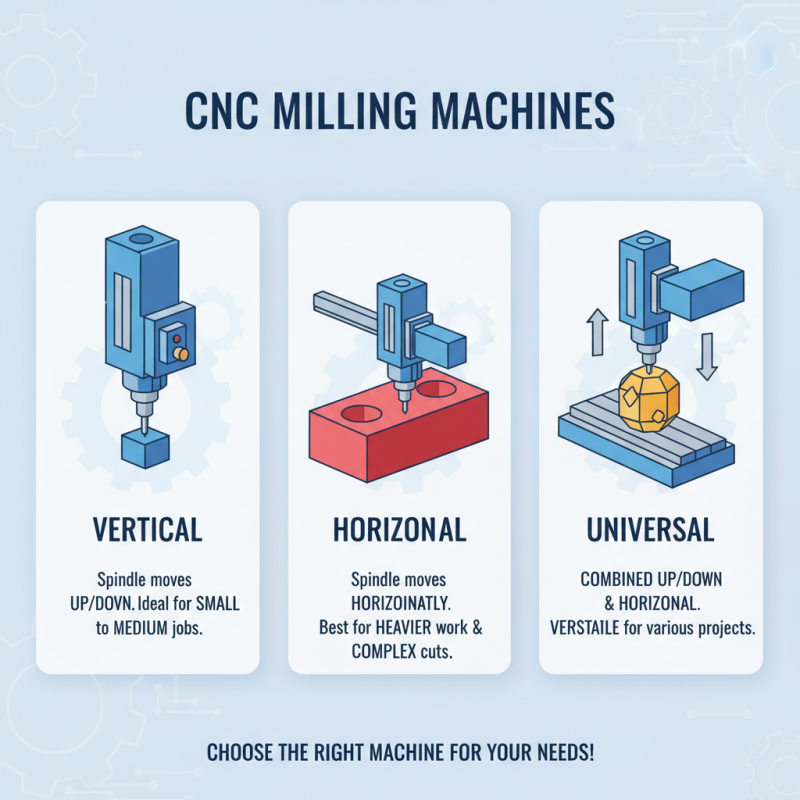

Understanding the Different Types of CNC Milling Machines Available Today

When choosing a CNC milling machine, it is vital to understand the various types available today. The most common types include vertical, horizontal, and universal milling machines. Vertical machines have a spindle that moves up and down. They are great for small to medium jobs. Horizontal machines, on the other hand, have a spindle that moves horizontally. These are better for heavier workpieces and complex cuts. Universal milling machines can handle both orientations, offering versatility for various projects.

Tips: Think about your specific needs. What materials do you often work with? Different machines may excel with different materials. You might find that a vertical machine is adequate for aluminum but struggles with steel. Investigate the machine's capabilities before making a decision.

Consider the size of the job. A large-scale project may require a machine with a broader worktable. A compact machine might be suitable for smaller tasks but could fall short on bigger projects. Reflect on your workspace as well. If your shop is small, a massive machine might not be a good fit. Always measure your space before making a commitment.

Key Features to Consider When Selecting a CNC Milling Machine

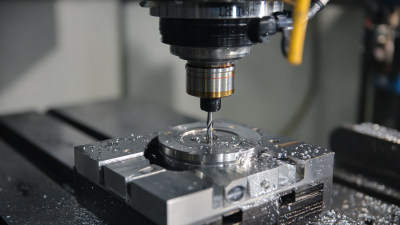

When selecting a CNC milling machine, understanding key features is crucial. One important aspect is machine rigidity. A more rigid machine ensures better accuracy and a longer tool life. According to recent industry reports, a machine's rigidity can improve precision by up to 30%. This directly impacts the quality of the finished product.

Another feature to consider is the spindle speed range. A higher spindle speed can enhance material removal rates. Most machines today offer speeds ranging from 1,000 to 24,000 RPM. However, it's essential to assess if this speed aligns with your typical materials. The wrong choice might lead to reduced efficiency or increased wear.

Control systems are also significant. Advanced CNC systems provide better programming capabilities and ease of use. Yet, complexity can be overwhelming for some operators. A simpler interface may lead to better productivity in daily operations. Assessing the skill level of your team is vital in making the right decision. Ultimately, reflect on your specific needs before making this important investment.

Evaluating Precision and Accuracy: Essential Metrics for CNC Milling

When choosing a CNC milling machine, precision and accuracy are key factors. Precision refers to the machine's ability to produce consistent results over time. It measures how well the machine can replicate the same operation. Accuracy, on the other hand, relates to how close the finished measurement is to the intended dimensions. Both metrics are crucial for different applications.

Consider the specifications of the machine. Look for the tolerance levels indicated in microns. Machines with tighter tolerances offer better precision. A tolerance of 10 microns is impressive. Ensure that the machine can handle the materials you plan to use. Testing different speeds can reveal how they impact performance. Sometimes, it is easy to overlook these details when focused on other features. Each machine has strengths and weaknesses. Reflect on what metrics matter most for your specific needs.

Precision and Accuracy Metrics for CNC Milling Machines

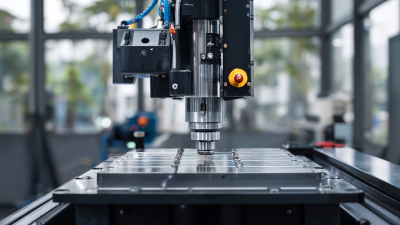

The Importance of Size and Capacity in CNC Milling Machines

When selecting a CNC milling machine, size and capacity are critical factors. The size of the machine determines the types of projects you can undertake. A compact machine may fit into small workshops but could limit your ability to work on larger pieces. On the other hand, an oversized machine could dominate your workspace. Balancing size with your operational needs requires reflection on your current and future projects.

Capacity speaks to what materials you can work with and how complex your parts can be. A machine with a higher capacity can handle tougher materials, such as titanium or hardened steel. However, with such power comes increased costs and maintenance. Understanding your common materials is vital. Consider if your projects require intricate designs or larger, simple cuts.

It's also important to think about the future. Your needs may change, and what works today might not serve tomorrow. Invest time in assessing both your immediate and long-term requirements. It's a common oversight to focus solely on current tasks, neglecting potential growth. Take a moment to envision where your production may lead.

How to Choose the Best CNC Milling Machine for Your Needs? - The Importance of Size and Capacity in CNC Milling Machines

| Criterion | Description | Example Values |

|---|---|---|

| Machine Size | Physical dimensions of the machine, impacting the workspace. | Length: 1000mm, Width: 800mm, Height: 600mm |

| Table Size | Size of the work table where materials are placed. | Length: 750mm, Width: 400mm |

| Weight Capacity | Maximum weight that the machine can handle during milling. | 1500 kg |

| Axis Movement | The number of axes the machine can operate on. | 3-Axis, 5-Axis |

| Spindle Power | Power of the spindle motor, affecting cutting capabilities. | 3 kW, 5 kW |

| Control Type | Type of control system in use for operating the machine. | CNC Controller, PC-Based Control |

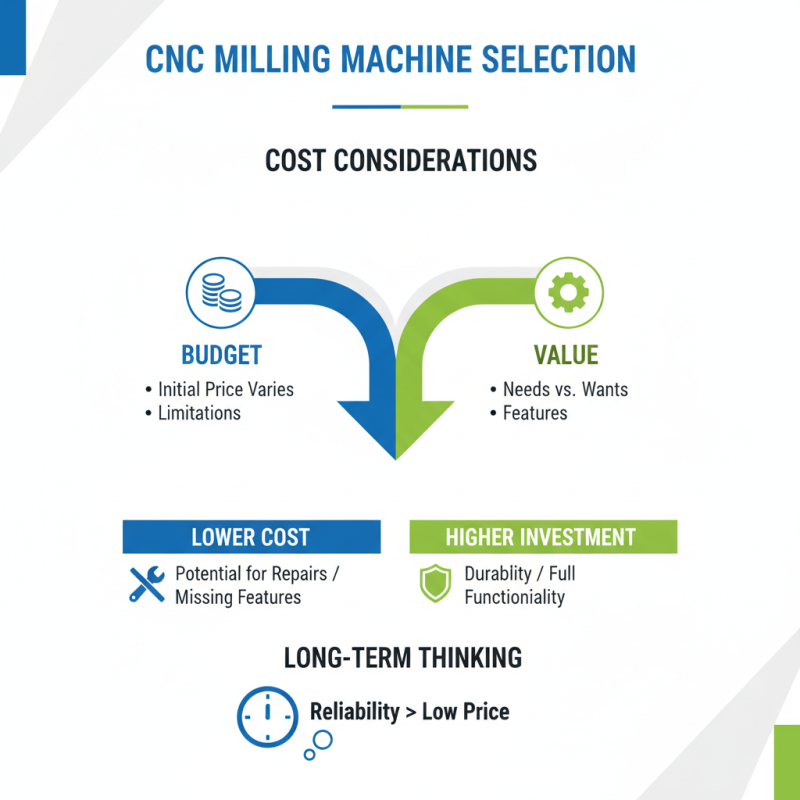

Cost Analysis: Choosing a CNC Milling Machine that Fits Your Budget

When selecting a CNC milling machine, cost is often a primary concern. Machines vary in price significantly. Budget limitations can affect your choices. However, it is essential to understand what you truly need versus what you want. For example, a lower-cost machine might lack critical features. Think about the long term, though. A machine that is cheap now might cost more in repairs later.

Consider additional costs when analyzing your budget. Maintenance fees, tool replacements, and software upgrades add up. Also, think about the space you have. A larger machine often comes with higher operational costs. Find balance. You need a machine that meets your requirements without overspending.

Reflect on your projects and production needs. Do you require high precision? If so, invest in quality. Don't compromise too much on key features. It's easy to get swayed by shiny add-ons. Identify what’s essential for your workflow. In the end, a thoughtful budget analysis can guide you to the right CNC milling machine for your workshop without breaking the bank.

Related Posts

-

Understanding Global Manufacturing Standards for Best CNC Milling Processes

-

Navigating Import Export Certifications for Best CNC Metal Products with Practical How to Strategies

-

Exploring the Features and Applications of the Best CNC Milling Machines for Every Industry

-

Versatile Applications of the Best Home CNC Machine in Diverse Industries

-

Exploring the Unique Features and Applications of Various CNC Router Machine Alternatives

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information