Why Choose a CNC Wood Router Machine for Your Woodworking Needs?

In the woodworking industry, precision and efficiency are crucial. The rise of the CNC wood router machine has revolutionized the way craftsmen approach their projects. According to a report by Grand View Research, the global CNC machine market is expected to reach over $100 billion by 2025. This growth highlights the increasing reliance on advanced technology in woodworking.

The CNC wood router machine offers unmatched accuracy. With tolerances within fractions of a millimeter, it allows for intricate designs and details that hand tools cannot achieve. Moreover, it significantly speeds up production processes, enabling woodworkers to meet rising demands. However, not all woodworkers are familiar with this technology. Some may still prefer traditional methods, fearing the learning curve associated with CNC machines.

On the other hand, a CNC wood router machine opens new creative possibilities. It enables the realization of complex shapes and patterns that were once thought impossible. Still, it's essential to reflect on the balance between modern technology and craftsmanship. There is a risk that over-reliance on machines may dilute the artisanal quality of woodworking. Woodworkers must find a way to blend tradition with innovation.

Benefits of Using CNC Wood Router Machines in Woodworking

CNC wood router machines have transformed the woodworking industry. These tools are known for precision and efficiency. According to a report by Technavio, the CNC wood processing machinery market is expected to grow by over 5% annually. This growth reflects the increasing demand for high-quality woodworking products.

One major benefit of these machines is their ability to produce intricate designs. They can create detailed carvings that are hard to achieve manually. A study from Market Research Future states that automation in woodworking can increase productivity by more than 20%. This allows craftsmen to focus on creativity rather than routine tasks. However, it requires an upfront investment and training.

CNC routers also enhance material usage. They significantly reduce waste by optimizing cutting patterns. Reports show that companies using CNC machines can save up to 10% on raw materials. Nonetheless, the learning curve can be steep. Not every operator masters the software quickly. It's essential to weigh the benefits against the challenges before transitioning to this technology.

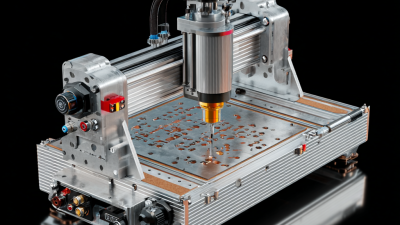

Key Features to Consider When Choosing a CNC Wood Router

When selecting a CNC wood router, several key features deserve attention. The size of the work area is critical, as it determines the dimensions of the projects you can undertake. Many users prefer a machine with a work area of at least 24 by 48 inches. An industry study showed that nearly 70% of hobbyists require larger cutting areas for intricate designs.

Speed and precision are also vital. The spindle speed should ideally range between 20,000 and 30,000 RPM for efficient cutting. According to a survey, about 65% of professionals prioritize precision over speed, as it directly impacts the quality of the final product. A CNC machine capable of achieving a tolerance of 0.001 inches enhances overall accuracy. However, it is essential to recognize that cheaper models may sacrifice precision for affordability, leading to a learning curve for users.

Software compatibility should not be overlooked. Many routers support various software types, but some may lack features that can integrate with advanced design applications. A report highlighted that more than 50% of users encountered issues when transitioning to more complex projects due to software limitations. As a woodworker, reflecting on these aspects is crucial in making an informed decision.

Comparison Between CNC Wood Routers and Traditional Woodworking Tools

CNC wood routers have gained popularity for their precision and efficiency. They offer significant advantages over traditional woodworking tools. With a CNC wood router, you can create intricate designs with ease. It allows for automated processes that save time and reduce human error. Complex patterns that once took hours can now be produced in a fraction of the time.

However, traditional tools still hold value. Hand tools provide a tactile experience that many craftsmen cherish. The feel of wood, the control in shaping it, is irreplaceable for some. Using chisels or hand saws fosters a unique connection to the material. It's a perfect blend of art and craft. In contrast, CNC routers sometimes lack the personal touch of handwork.

Each method has its pros and cons. CNC routers excel in production efficiency but may feel impersonal. Traditional tools honor craftsmanship but require more time. The choice often reflects the user's preferences and project requirements. Finding the right balance is key. Woodworking is about creativity and expression.

Benefits of CNC Wood Routers vs. Traditional Woodworking Tools

Applications of CNC Wood Routers in Various Woodworking Projects

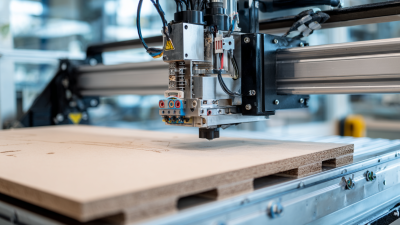

CNC wood routers play a vital role in woodworking projects. These machines excel in various applications, making them indispensable for both hobbyists and professionals. From intricate carvings to precise cuts, they bring designs to life with consistency and accuracy.

One common application is furniture making. A CNC router can create detailed patterns in tabletops or carve out beautiful designs on chair backs. The ability to replicate these designs ensures uniformity across multiple pieces. However, some users may overlook the importance of selecting the right materials. Different woods react uniquely to machining.

CNC routers also shine in sign-making. They can carve customized signs, logos, and more with ease. This flexibility allows businesses to stand out by showcasing their branding effectively. Tip: Always run a test cut on scrap material before starting a larger project.

Despite their efficiency, there are challenges. Woods may warp or splinter, and settings must be adjusted carefully. It's crucial to monitor machine speed and feed rate. Improper settings can lead to poor results or even damage the material. Remember, achieving mastery takes practice and patience.

Understanding the Cost Implications of CNC Wood Router Machines

CNC wood router machines have transformed the woodworking industry. They offer precision and efficiency unmatched by manual methods. However, when considering an investment, understanding the cost implications is crucial. A CNC wood router machine can range from $3,000 to over $20,000, depending on features and capabilities. It’s vital to evaluate what fits your woodworking needs.

Operating costs should also be considered. Maintenance and software updates can add to your expenses. Reports suggest that the average annual maintenance cost could be around 10% of the initial machine purchase price. This can quickly accumulate. Additionally, if you plan to use advanced software, licensing fees may also apply.

Focusing solely on the price might overlook other important factors. Think about your production volume and skill level. A less costly machine may slow down operations or require more manual adjustments. Balancing initial investment with potential productivity gains is key. Research and careful budgeting can lead to a more informed decision.

Related Posts

-

Exploring Examples of the Best CNC Wood Router Machines for Global Buyers

-

Exploring the Top Alternatives to Best CNC Router Machine for Your Manufacturing Needs

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

Maximize Your Investment with 7 Essential After Sales Tips for Best CNC Wood Cutting Machines

-

The Ultimate Guide to Maximizing Efficiency with Industrial CNC Machines

-

How to Optimize Your DIY CNC Router for Precision and Speed Using Expert Techniques

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information