How to Choose the Best Portable CNC Machine for Your DIY Projects

In the world of DIY projects, the demand for precision and versatility has made the portable CNC machine an indispensable tool for hobbyists and professionals alike. According to industry expert John Smith, a renowned figure in the field of computer numerical control technology, “The right portable CNC machine can transform an idea into reality with unmatched accuracy and efficiency.” As more makers and innovators seek to enhance their craftsmanship, understanding how to select the best portable CNC machine becomes essential.

When exploring options for a portable CNC machine, various factors such as size, functionality, and ease of use come into play. Whether you’re designing intricate patterns for woodworking, creating custom parts for your automotive needs, or crafting personalized gifts, the right machine can significantly impact your project's outcome. With advancements in technology and increased accessibility to these powerful tools, enthusiasts are empowered to achieve remarkable results right in their own workshops.

In this guide, we will delve into key considerations to help you make an informed decision when choosing a portable CNC machine, ensuring that your DIY projects are equipped with the best tools to turn your creative visions into tangible products.

Understanding the Basics of Portable CNC Machines

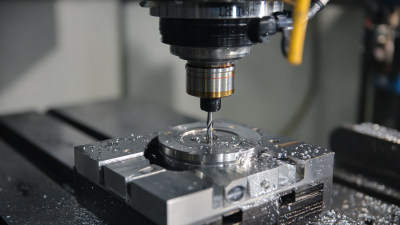

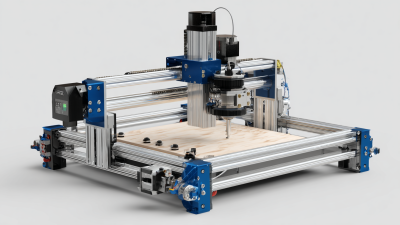

Portable CNC machines have gained immense popularity among DIY enthusiasts and professionals alike, offering the precision and efficiency of CNC technology in a compact form. Understanding the fundamentals of these machines is crucial for selecting the best one for your projects. Fundamentally, portable CNC machines can cut, engrave, and carve various materials, including wood, plastics, and even metals. According to a report by Research and Markets, the global CNC market is expected to grow significantly, reflecting the increasing trend towards automation in creative projects.

When choosing a portable CNC machine, consider the machine's capabilities, such as its cutting area, speed, and supported materials. Machines with a larger cutting area can handle bigger projects but may require more space in your workshop. Pay attention to the spindle speed, as a higher speed usually translates to smoother cuts and faster operation. Additionally, ensure the software compatibility with your design programs, as this will streamline your workflow.

**Tips:** Look for machines that offer a clear setup guide and have an active user community for support. This can significantly ease the learning curve for beginners. Additionally, assess the machine's build quality and stability to ensure accuracy and durability during operation, as these factors can directly influence the outcome of your DIY projects.

Comparison of Key Features in Portable CNC Machines

This bar chart compares several essential features of portable CNC machines, helping you understand the key attributes to evaluate when selecting the best option for your DIY projects. The parameters include accuracy, weight, maximum cutting depth, price, and material support.

Key Features to Consider While Choosing a Portable CNC Machine

When selecting a portable CNC machine for your DIY projects, there are several key features to consider that can greatly impact your workflow and the quality of your finished products.

Firstly, assess the machine's cutting area—measurements of at least 12” x 12” are common for personal projects, but larger areas provide versatility for bigger pieces.

Additionally, consider the spindle speed and power; a machine with higher RPM ratings generally cuts materials more efficiently, allowing you to achieve smoother finishes on various substrates like wood, plastics, and even soft metals.

Another important feature is the software compatibility. Many portable CNC machines come with proprietary software, but the ability to integrate with popular CAD/CAM programs offers greater flexibility and functionality. According to industry reports, about 65% of hobbyists prioritize software that supports both 2D and 3D design capabilities, highlighting the need for versatility in your chosen equipment.

Tips: Always check for user reviews and community support regarding a machine's reliability and ease of use, as these factors can significantly shorten your learning curve.

Additionally, look for machines with a robust customer service offering—real-time assistance can save you time and frustration during complex projects.

Lastly, keep in mind the portability aspect; lightweight machines with a compact design are more favorable for those who need to move their equipment frequently or work in various locations.

Assessing Your DIY Project Requirements for CNC Usage

When assessing your DIY project requirements for CNC usage, the first step is to clearly define the types of materials you plan to work with. Different projects may require the use of wood, metal, plastic, or composite materials, each of which interacts differently with CNC machinery. Understanding the properties of these materials will help you determine the appropriate cutting speed, bit type, and machine capabilities needed to achieve precise and clean results. For instance, softer materials like wood may allow for a wider range of machine options, whereas metals might necessitate a more robust CNC machine designed to handle tougher cutting processes.

Next, consider the size and complexity of your intended projects. The dimensions of your workspace and the scale of your projects will influence the size of the portable CNC machine that best fits your needs. If your projects typically involve intricate designs or larger pieces, you will need a machine that offers a bigger work area or has supporting features like a higher resolution or advanced software for intricate designs. Additionally, it's essential to think about how often you will use the machine and whether you need portability to transport it between locations or to store it conveniently when not in use. Balancing these factors will guide you toward selecting a machine that aligns perfectly with your DIY ambitions.

How to Choose the Best Portable CNC Machine for Your DIY Projects

| Feature | Importance for DIY Projects | Recommended Specifications |

|---|---|---|

| Portability | Essential for easy movement and storage | Weight under 25 lbs |

| Cutting Area | Determines the size of projects you can undertake | At least 12" x 12" |

| Material Compatibility | Allows working with different materials like wood, plastic, and metal | Compatible with at least wood and plastic |

| Precision | Critical for detailed DIY projects | Tolerance within 0.01 mm |

| Ease of Use | Affects the learning curve and sustainability of use | User-friendly software and setup |

| Price | Must fit budget constraints for DIY enthusiasts | Under $1000 |

Comparing Popular Portable CNC Machines on the Market

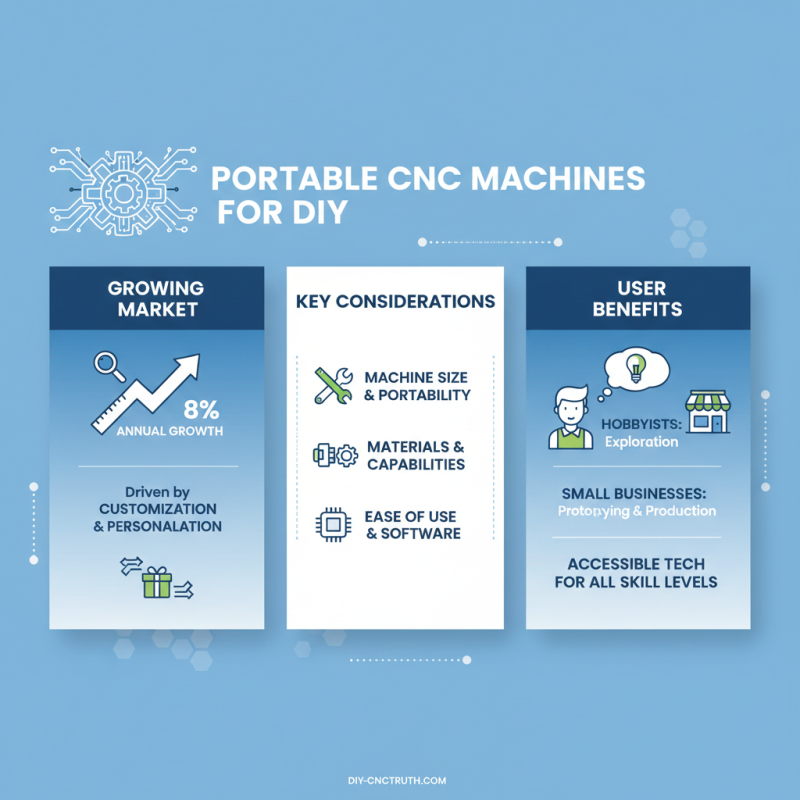

When selecting a portable CNC machine for DIY projects, it is essential to consider the varied options available in the market. Recent industry reports suggest that the portable CNC machine market has seen a significant growth rate of around 8% annually, driven by increasing interest in personalized and customizable products among hobbyists and small business owners. These machines are becoming more accessible, offering features that cater to both novice and experienced users.

Key factors to compare include cutting area, maximum spindle speed, and software compatibility. In particular, cutting area varies widely among machines, typically ranging from 12x12 inches to as large as 24x24 inches, impacting the type of projects that can be efficiently undertaken. Additionally, spindle speeds often range from 6,000 RPM to 30,000 RPM, influencing the materials that can be effectively processed, such as wood, plastics, and metals. Software compatibility is also crucial; many machines integrate well with popular CAD/CAM software, which allows for smoother transitions from design to fabrication.

The current trend indicates that users prioritize user-friendliness, with features like touch screens, built-in tutorials, and cloud-based design access being particularly appealing. Additionally, portability and ease of setup remain critical, as many consumers need a compact solution that is easy to transport and quick to deploy. Understanding these features and specifications can greatly enhance the choice for DIY enthusiasts looking to invest in a portable CNC machine that best fits their creative and practical needs.

Evaluating Budget and Long-Term Investment for CNC Equipment

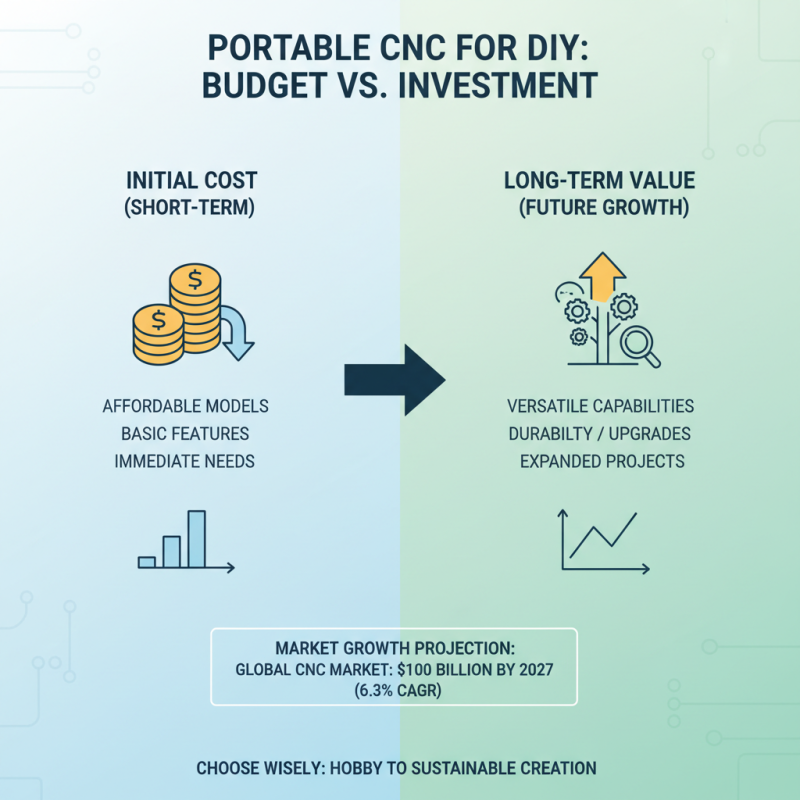

When considering the purchase of a portable CNC machine for DIY projects, evaluating budget alongside long-term investment potential becomes crucial. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2027, growing at a CAGR of 6.3% from 2022. This growth indicates a strong demand for versatile and affordable CNC options, highlighting the importance of selecting a machine that not only meets immediate needs but also serves as a sustainable investment for future projects.

Initial costs can vary widely based on machine capabilities, features, and precision levels. Entry-level portable CNC machines can start around $500, whereas more advanced models may exceed $5,000. It's essential to consider the overall cost-of-ownership, which goes beyond the purchase price. Factors such as durability, maintenance, and the availability of replacement parts can significantly affect long-term expenses. A well-chosen machine can enhance productivity and precision, leading to better project outcomes and reducing the need for costly reworks, which, according to a study by the Project Management Institute, can add up to 20% of total project costs if not managed properly. Thus, investing in a reliable portable CNC machine can yield substantial returns over time, making budget considerations crucial for DIY enthusiasts and professionals alike.

Related Posts

-

Understanding Global Manufacturing Standards for Best CNC Milling Processes

-

Discover the Finest Portable CNC Machines from China's Leading Manufacturers

-

Navigating Import Export Certifications for Best CNC Metal Products with Practical How to Strategies

-

Exploring the Unique Features and Applications of Various CNC Router Machine Alternatives

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

The Ultimate Guide to Maximizing Efficiency with Industrial CNC Machines

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information