Why is CNC Metal Machining Important for Modern Manufacturing?

CNC metal machining is essential in modern manufacturing. According to industry reports, about 70% of manufacturers rely on CNC technologies for precision machining. This technology enhances accuracy, reduces waste, and optimizes production time. In a report by MarketsandMarkets, the global CNC machining market is projected to grow significantly, reaching over $100 billion by 2025.

CNC metal machining allows manufacturers to produce complex designs with tight tolerances. This process empowers industries like aerospace, automotive, and medical. However, challenges still exist. Many companies struggle with integrating new CNC technologies into existing systems. Training staff adequately remains a recurring issue.

Additionally, while CNC metal machining improves efficiency, companies may overlook maintenance. Regular upkeep is crucial to avoid costly downtimes. As the industry evolves, keeping pace with technological advancements poses a challenge. Despite these hurdles, embracing CNC metal machining is crucial for staying competitive in today's manufacturing landscape.

CNC Metal Machining: An Overview of Its Role in Manufacturing

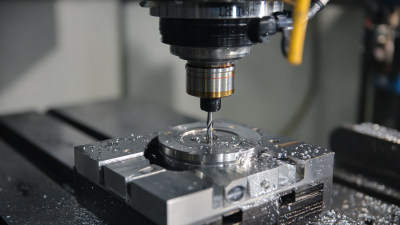

CNC metal machining is pivotal in modern manufacturing. This technology uses computer-controlled tools to shape metal precisely. It allows for complex designs that were previously difficult to achieve. Many manufacturers rely on CNC machining for efficiency and accuracy. This method saves time, reducing production costs significantly.

The versatility of CNC machining means it can work with various metals. Steel, aluminum, and titanium are commonly used materials. Each metal has unique properties that suit different applications. However, not all designs can be effectively machined. Some require a learning curve and deeper analysis. Errors can lead to waste, which manufacturers cannot afford.

Despite its advantages, challenges persist. Skilled operators are essential to ensure precision during machining. Overlooking minor details may result in significant setbacks. Additionally, the initial setup cost for CNC machines can be high. It demands careful financial planning. Balancing automation and manual skills is crucial for optimization. Manufacturers must continually assess their processes for improvements.

The Evolution of CNC Machining Technology in the Manufacturing Sector

CNC machining has undergone significant changes over the past few decades. Originally, it relied heavily on manual programming. Today, advanced software automates much of the process. This evolution has increased precision and efficiency in production. Modern CNC machines can perform complex cuts with minimal human intervention. The speed at which products can be manufactured has accelerated dramatically.

Tips: Regular maintenance of CNC machines is crucial. Neglected machines can lead to production issues. Always monitor tool wear; this can enhance accuracy and reduce costs over time.

The integration of CAD/CAM systems has transformed CNC machining. Designers and engineers can now create intricate designs with ease. This synergy allows for rapid prototyping. However, over-reliance on software can result in less hands-on experience for operators. Some may find this shift concerning, as intuition can sometimes be lost.

Tips: Invest time in training for operators. Understanding the fundamentals of machining remains vital. Encourage a blend of technology and traditional skills to maintain quality.

Key Benefits of CNC Metal Machining for Precision Engineering

CNC metal machining plays a pivotal role in modern manufacturing. It enhances precision, ensuring that components fit together seamlessly. This technology uses computer-controlled tools to create complex shapes. The result is high-quality parts, which are crucial for industries like aerospace and automotive. Precision engineering relies heavily on this method.

When implementing CNC machining, consider its efficiency. It can reduce human error and speed up production. This leads to cost savings over time. However, it’s essential to calibrate machines regularly. Small inaccuracies can lead to significant issues later on. Tips: always double-check initial settings.

Another major benefit is the versatility of CNC machining. It can work with various materials, from aluminum to steel. This adaptability opens up countless possibilities in design. Yet, many overlook the need for thorough training. Operators must understand the equipment fully. Tips: invest time in operator education. Adjustments and maintenance require skill and care. By acknowledging these areas, manufacturers can truly harness the power of CNC machining.

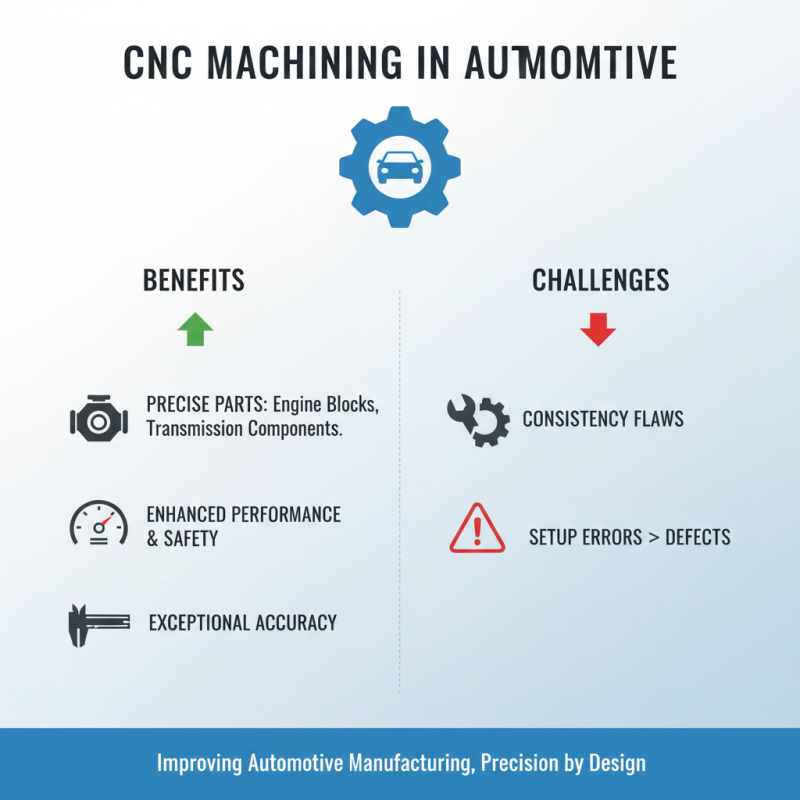

Applications of CNC Machining in Various Industries

CNC machining plays a crucial role in multiple industries. In the automotive sector, it enables precise part manufacturing. Components like engine blocks and transmission parts are crafted with exceptional accuracy. This precision improves vehicle performance and safety. However, challenges in achieving consistency can arise. Flaws in initial setups might lead to defects.

The aerospace industry also relies heavily on CNC machining. Parts must meet strict safety standards. Machining contributes to the creation of lightweight, strong components. These lightweight parts enhance fuel efficiency. Yet, maintaining quality remains a constant challenge. Variations in materials can affect the final product.

In medical device manufacturing, CNC machining is essential for creating intricate designs. Custom implants and surgical instruments require high precision. Patients' safety hinges on these products meeting exact specifications. Despite advancements, manufacturers must continually address the risk of error. Continuous improvement is necessary to keep pace with evolving technologies. Each sector's reliance on CNC machining highlights its importance in modern manufacturing.

Future Trends in CNC Metal Machining and Manufacturing Innovations

CNC metal machining is evolving rapidly. Future trends indicate a shift towards automation and smart manufacturing. According to a recent report by McKinsey, automation can boost productivity by up to 25% in manufacturing sectors. Companies are integrating AI to enhance decision-making and precision machining. Even though the technology is promising, it requires significant investment and training.

Additive manufacturing, or 3D printing, is also making waves. A study by Wohlers Associates reveals that the 3D printing market is projected to grow to $44.4 billion by 2025. This growth challenges traditional CNC methods, pushing engineers to rethink design approaches. However, not all parts can be effectively produced this way.

Sustainability is another key trend. Businesses face pressure to adopt environmentally-friendly practices. A survey by Deloitte shows that 48% of manufacturers plan to implement sustainable processes within the next three years. Yet, achieving this can be difficult. Companies must balance costs and sustainability. The future of CNC machining holds potential but also demands careful consideration of efficiency and innovation.

Related Posts

-

Understanding Global Manufacturing Standards for Best CNC Milling Processes

-

Navigating Import Export Certifications for Best CNC Metal Products with Practical How to Strategies

-

Exploring the Unique Features and Applications of Various CNC Router Machine Alternatives

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

The Ultimate Guide to Maximizing Efficiency with Industrial CNC Machines

-

Why Investing in CNC Machines Can Boost Your Production Efficiency by 30% Financially

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information