Top CNC Metal Machining Techniques for Precision Parts in 2023

In the realm of advanced manufacturing, CNC metal machining has emerged as a critical process for producing precision parts that meet the stringent requirements of various industries. According to Dr. Emily Hart, a renowned expert in CNC metal technologies, "The accuracy and efficiency offered by CNC metal machining are unparalleled, enabling manufacturers to push the boundaries of innovation." As we move further into 2023, it's essential to explore the top CNC metal machining techniques that are shaping the future of engineering and production.

The demand for high-precision components is driving the evolution of CNC metal machining methods. In this highly competitive landscape, manufacturers are increasingly adopting new technologies to enhance their capabilities and improve product quality. From advanced toolpath strategies to state-of-the-art machines, the industry is witnessing significant advancements that empower engineers to create intricate designs with unparalleled accuracy.

In this article, we will delve into the most effective CNC metal machining techniques that can elevate production standards. By understanding these techniques, manufacturers can leverage the power of CNC metal machining to meet the needs of their customers while also optimizing efficiency and reducing production costs.

Top CNC Metal Machining Techniques for Precision Parts in 2023

In 2023, the landscape of CNC metal machining continues to evolve, showcasing advanced techniques that enhance precision and efficiency in part production. One of the standout methods is High-Speed Machining (HSM), which leverages rapid tool movement and optimized machining parameters. This technique minimizes cycle times and improves surface finishes, making it ideal for intricate designs that demand tight tolerances. By utilizing high RPMs and efficient chip removal strategies, manufacturers can achieve superior accuracy while maintaining productivity.

Another notable technique gaining traction is 5-Axis Machining, which allows for more complex geometries to be machined in a single setup. This capability reduces the need for multiple setups, consequently decreasing the risk of errors associated with part repositioning.

The flexibility of 5-axis machining enables the production of parts with undercuts and complex shapes that are difficult or impossible to achieve with traditional 3-axis methods. As the demand for intricate components increases across various industries, the adoption of these advanced machining techniques is essential for staying competitive and ensuring precision in manufacturing.

Advancements in CNC Milling: Trends and Capabilities for 2023

The landscape of CNC milling has witnessed significant advancements in 2023, driven by innovations in technology and increasing demand for precision parts across various industries. According to a recent industry report by the Technology & Engineering Institute, the global CNC milling market is projected to grow at a compound annual growth rate (CAGR) of 7.5% from 2023 to 2028, highlighting the essential role that CNC milling plays in modern manufacturing.

Key trends include the integration of artificial intelligence and machine learning algorithms, enabling smarter and more efficient machining processes. These technologies allow for real-time data analysis, which optimizes cutting parameters and enhances tool lifespan, thereby significantly reducing operational costs.

Moreover, the introduction of advanced materials and high-performance tooling has expanded the capabilities of CNC milling. Reports indicate that 40% of manufacturers have already adopted advanced ceramic and composite materials, which are essential for producing lightweight yet durable parts.

With sophisticated multi-axis machining centers now more widely accessible, manufacturers are achieving higher levels of complexity in part design, opening new avenues in industries such as aerospace and automotive. As a result, CNC milling is not only improving in efficiency but also in its ability to produce intricate geometries, thereby empowering manufacturers to meet the evolving needs of their clients in 2023 and beyond.

The Role of CNC Turning in High-Precision Component Manufacturing

CNC turning has emerged as a critical technique in the manufacturing of high-precision components, particularly in the field of metal machining. This process involves rotating a workpiece against a cutting tool, allowing for the creation of intricate geometries and tight tolerances that are essential for modern engineering applications. As industries increasingly demand components that meet stringent specifications, CNC turning provides the accuracy and repeatability needed to produce parts with minimal variation.

The versatility of CNC turning is one of its key advantages. It can handle a wide range of materials, including various metals and alloys, making it suitable for producing everything from simple shafts to complex prototypes. Additionally, advancements in CNC technology have led to more sophisticated machinery that can perform multiple operations—such as drilling and milling—during a single setup. This integration reduces production time and enhances efficiency, enabling manufacturers to meet the growing demands for high-quality precision parts in a timely manner. As we progress through 2023, CNC turning continues to be a cornerstone in the landscape of precision manufacturing, driving innovation and quality in various sectors.

Emerging Technologies: Laser Cutting and Its Impact on CNC Machining

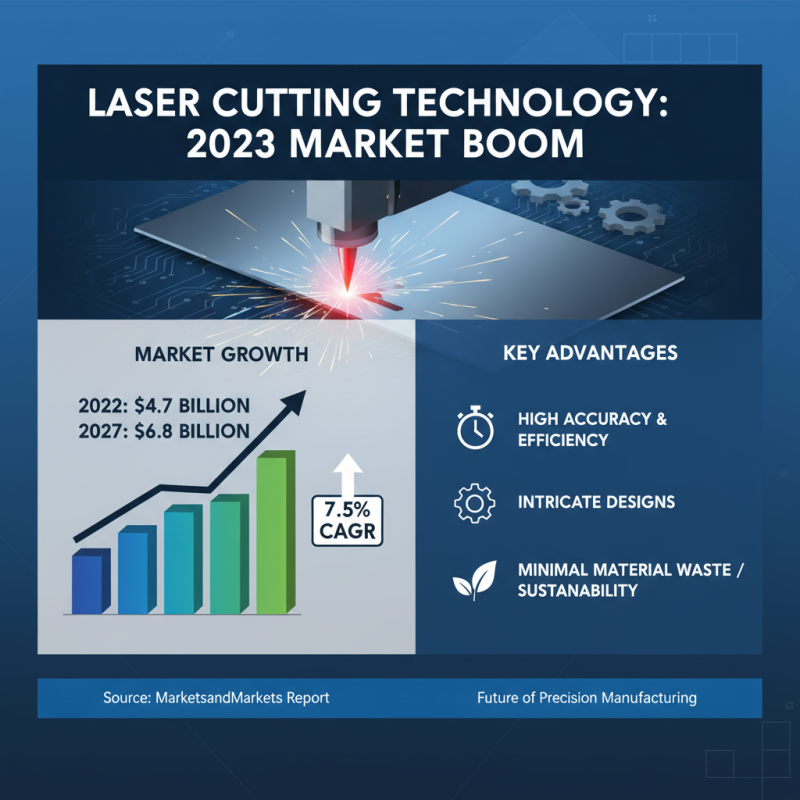

Laser cutting technology has rapidly emerged as a pivotal technique in CNC machining, revolutionizing the way precision parts are produced in 2023. According to a report by MarketsandMarkets, the laser cutting market is projected to grow from USD 4.7 billion in 2022 to USD 6.8 billion by 2027, at a compound annual growth rate (CAGR) of 7.5%. This growth can be attributed to the high accuracy and efficiency that laser cutting offers compared to traditional machining methods. Utilizing focused beams of light, laser cutting achieves intricate designs with minimal material waste, which is increasingly crucial in a market that demands both precision and sustainability.

The adoption of laser technology complements traditional CNC methods by enhancing flexibility and speed in production processes. Emerging applications in sectors such as automotive, aerospace, and electronics are driving demand for custom-designed components, and laser cutting stands out for its capability to handle complex geometries without the need for extensive tooling. Additionally, advancements in fiber laser technology allow for faster cutting speeds and improved energy efficiency, making it an attractive solution for manufacturers aiming to reduce operational costs while maintaining high standards of quality. As industries continue to embrace these innovations, laser cutting is set to play a key role in the future of CNC machining, solidifying its position as an essential technique for precision part fabrication.

Quality Control Measures in CNC Machining: Ensuring Precision Parts

In the realm of CNC machining, the importance of quality control measures cannot be overstated. Precision parts are vital in various industries, and ensuring their accuracy involves a comprehensive set of practices designed to minimize errors and maintain high standards. One of the primary methods employed is the use of statistical process control (SPC), which allows manufacturers to monitor and control the machining process by analyzing data and variations. By collecting measurements at different stages of production, any anomalies can be detected early, facilitating timely adjustments to equipment or processes.

Another significant quality control technique involves the implementation of rigorous inspection protocols. This typically includes the use of advanced measuring tools such as coordinate measuring machines (CMM) and laser scanners that provide detailed information about the dimensions and tolerances of the machined parts. Regular inspection helps in identifying deviation from the desired specifications, ensuring that any defective components are addressed before they reach the final stages of production. Furthermore, implementing a continuous feedback loop between the manufacturing and quality assurance teams can foster a culture of precision, leading to better end products and increased customer satisfaction.

Top CNC Metal Machining Techniques in 2023

Conclusion

In 2023, the landscape of CNC metal machining continues to evolve with advancements in technology and methodologies. Key trends in CNC milling are emphasizing increased capabilities, allowing for more intricate designs and greater efficiency. CNC turning plays a significant role in the manufacturing of high-precision components, showcasing its importance in achieving tight tolerances necessary for modern applications.

Emerging technologies such as laser cutting are also transforming traditional CNC metal machining processes, introducing enhanced speed and accuracy. Quality control measures are paramount to ensure that precision parts meet the stringent standards required in various industries. Additionally, careful material selection is crucial, guiding best practices to optimize performance and durability in CNC metal applications. Together, these elements contribute to the ongoing refinement of CNC machining techniques, paving the way for innovative solutions in precision parts manufacturing.

Related Posts

-

Unlocking Creative Manufacturing with Best Desktop CNC Applications and How to Get Started

-

Navigating Global Trade Standards for Best Desktop CNC Machine Import and Export

-

Future Trends in Global CNC Machinery Market Leading to the Best Home CNC Machine of 2025

-

10 Best Hobby CNC Machines for Creative Makers in 2023

-

Exploring Innovations in Portable CNC Machines at the 138th Guangzhou Trade Fair 2025

-

Top 10 Home CNC Machines for Beginners in 2023

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information