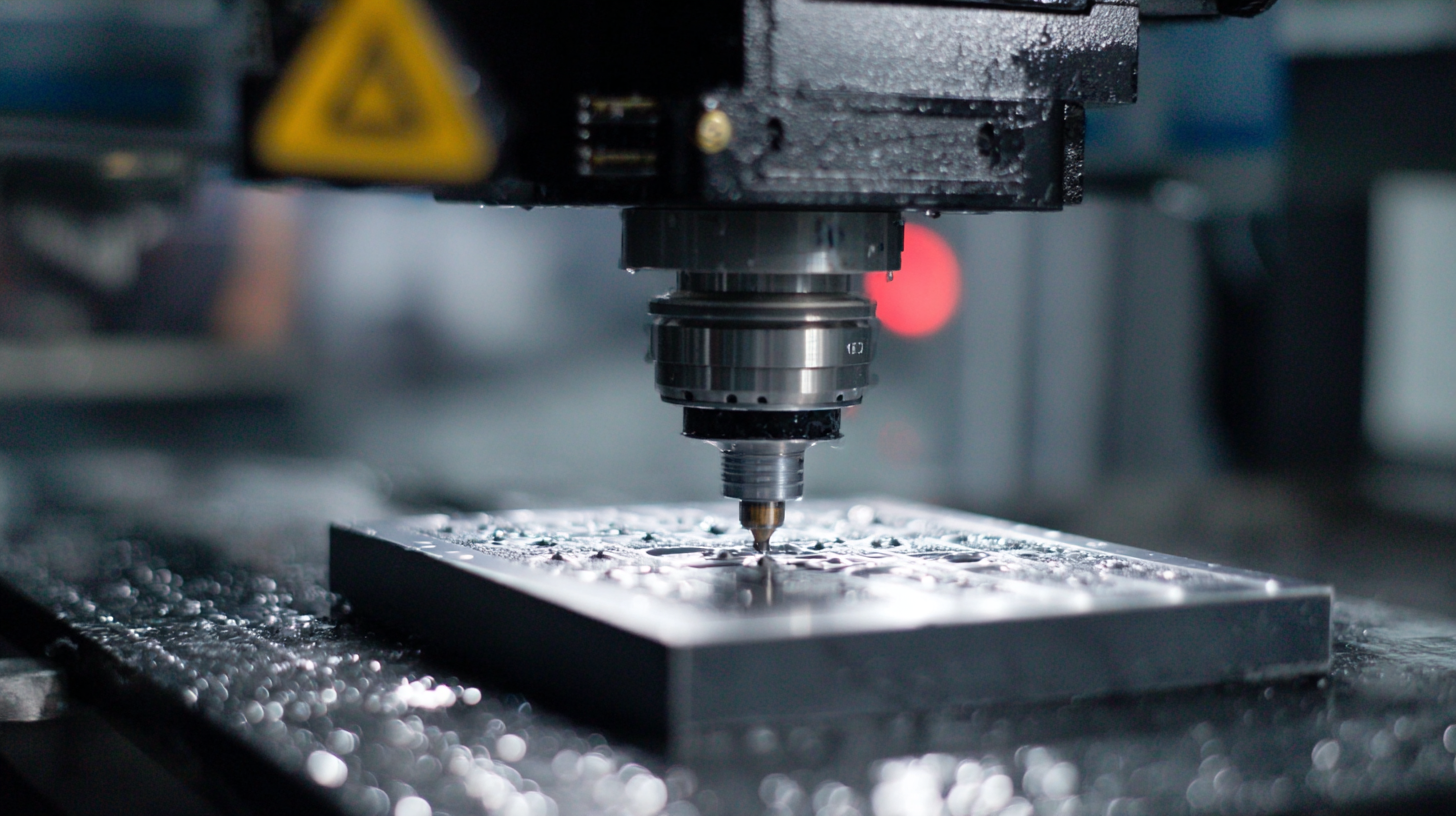

7 Essential Tips for Maximizing Precision with Your Home CNC Machine

As the popularity of home CNC machines continues to rise, participating in this innovative wave has never been more accessible. According to a recent report by MarketsandMarkets, the global CNC machine market size is projected to reach $117 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.9%. This surge highlights not only the growing interest among hobbyists and professionals alike but also the significance of optimizing precision for successful projects. Whether you are crafting intricate designs or functional parts, mastering the nuances of your home CNC machine can greatly enhance the quality of your outputs. In this blog, we will explore seven essential tips to help you maximize the precision of your machine and elevate your craftsmanship to new heights.

Understanding the Importance of Machine Calibration for CNC Precision

Calibration is a critical component in achieving precision with your home CNC machine. As the calibration services industry continues to grow, predicted to reach $8.1 billion by 2030, the importance of accurate machine calibration has never been clearer. Investing time in regular calibration ensures that your CNC machine operates within the necessary specifications, reducing errors that can lead to costly waste. Automated calibration systems are leading the charge by streamlining the calibration process—reducing manual intervention while enhancing overall measurement accuracy, which is essential for quality and efficiency in manufacturing.

Additionally, advanced verification methods are now available that allow for rapid calibration of CNC machines. These state-of-the-art systems can fully verify machine tools in just a few minutes, significantly minimizing downtime. As the technology evolves, shop owners need to move away from traditional methods, such as calibration cubes, which are no longer the most effective way to ensure precision. Embracing these modern approaches not only boosts productivity but also enhances profitability, establishing a robust foundation for any CNC operation.

Essential Software Tools for Enhancing CNC Machining Accuracy

When it comes to enhancing the accuracy of your home CNC machine, the right software tools can make a significant difference. One essential tool is a reliable CAM (Computer-Aided Manufacturing) software that allows you to generate precise tool paths. Utilizing advanced settings like feed rates and spindle speeds tailored to your material can drastically improve cutting precision. Always ensure your software is updated to leverage new features that could enhance your machining capabilities.

Another critical software tool is simulation software, which provides a virtual environment to test your designs before they are executed on the CNC machine. This allows you to identify potential issues early on, reducing material waste and improving overall efficiency. Before starting a project, run your tool paths through the simulator to check for errors or collisions, ensuring that your machine operates smoothly.

Lastly, consider using nesting software if you frequently work with sheets of material. Nesting software optimizes the layout of your designs, minimizing material wastage and ensuring that each part is cut with the utmost precision. By integrating these software tools into your CNC workflow, you can significantly boost your machining accuracy and achieve more professional results in your home projects.

7 Essential Tips for Maximizing Precision with Your Home CNC Machine

Material Selection: Impact on Precision in CNC Projects

Material selection is a crucial factor that can significantly impact precision in CNC projects. According to a report by the National Institute of Standards and Technology (NIST), material properties such as hardness, density, and thermal expansion coefficients play a major role in machining processes. For instance, harder materials like titanium require slower feed rates and specific tooling to maintain precision, as high-speed cutting can lead to tool wear and inaccuracies. Selecting the appropriate material not only influences the quality of the final product but also affects the overall efficiency of the CNC operation.

Additionally, different materials respond uniquely to various machining techniques. A study published in the Journal of Manufacturing Science and Engineering revealed that softer materials, such as plastics and aluminum, can be more forgiving during the machining process, allowing for higher feed rates and deeper cuts without compromising precision. Conversely, more complex materials like composites may require specialized strategies and considerations, as their layered structures can lead to unpredictable behavior during machining. Adapting your approach based on material selection can markedly enhance the accuracy of your projects and reduce errors, ensuring that your home CNC machine operates at its optimal level.

Best Practices for Tool Maintenance to Ensure CNC Precision

When it comes to achieving optimal precision with your home CNC machine, maintaining your tools is of utmost importance. One of the best practices to ensure CNC precision is regular inspection and cleaning of cutting tools. Over time, debris and residue can accumulate, leading to compromised accuracy and reduced tool life. Take the time to carefully wipe down your tools after each use, and use appropriate solvents or brushes to remove any stubborn buildup. A clean tool not only performs better but also contributes to a smoother machining process.

In addition to cleaning, sharpening your tools regularly can significantly enhance precision. Dull blades create friction and irregular cuts, which can compromise the quality of your work. Depending on the frequency of your usage, establish a routine for tool sharpening—whether it’s every few projects or weekly. For those serious about their CNC machining, investing in a good sharpening system can pay off in the long run, ensuring that your tools always operate at peak performance. By prioritizing tool maintenance, you'll find that your CNC projects yield higher accuracy and better finishes, truly maximizing the capabilities of your home machining setup.

7 Essential Tips for Maximizing Precision with Your Home CNC Machine

| Tip | Description | Frequency | Impact on Precision |

|---|---|---|---|

| Regular Tool Inspection | Check the condition of the tools before starting a job to prevent defects. | Before each job | High |

| Proper Lubrication | Keep moving parts adequately lubricated to reduce wear and tear. | Weekly | Medium |

| Calibration Checks | Regularly calibrate CNC machine settings to ensure accuracy. | Monthly | High |

| Clean Cutting Area | Ensure the workspace is free from debris to prevent errors. | Daily | High |

| Tool Storage | Store tools properly to avoid damage and maintain sharpness. | After each use | Medium |

| Software Updates | Keep CNC software up to date to leverage the latest features. | Quarterly | Low |

| Experiment with Feeds and Speeds | Adjust cutting speeds and feed rates for optimal results based on material. | As needed | High |

Utilizing Advanced Techniques for Optimal CNC Machine Settings

When maximizing precision with your home CNC machine, utilizing advanced techniques is essential, especially in settings where accuracy and efficiency are paramount. Recent advancements in high-speed machining, such as the implementation of optimally calibrated settings, have demonstrated significant improvements in cutting efficiency and surface quality. For instance, CYCLE832 settings for 3 and 5-axis free-form surfaces not only enhance efficiency but also ensure precise execution of intricate designs, which is vital in applications ranging from aerospace components to intricate artistic creations.

Incorporating machine learning algorithms for real-time monitoring of tool health further elevates the precision of CNC operations. A study highlighted the effectiveness of machine learning in diagnosing faults in CNC hobbing cutters by analyzing three-axis vibration data, enabling operators to foresee potential issues before they escalate. Additionally, the optimization of process parameters through methodologies like response surface analysis has shown promising results for materials such as mild steel and EN 24 steel, indicating that tailored adjustments based on material properties can yield considerable improvements in product quality. Embracing these advanced techniques is crucial for hobbyists and professionals alike looking to enhance their CNC machining capabilities.

Related Posts

-

Solutions for Optimal CNC Router Kit Performance

-

Versatile Applications of the Best Home CNC Machine in Diverse Industries

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

2025 Market Insights: How to Choose the Best CNC Engraver for Your Business Needs

-

Unique CNC Engraver Applications: Discover Innovative Uses for Your Projects

-

Top Strategies for Maximizing Efficiency with Desktop CNC Mills in Modern Manufacturing

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information