The Evolution of Industrial CNC Technology and Its Impact on Manufacturing Efficiency

The evolution of industrial CNC technology has revolutionized the landscape of modern manufacturing, dramatically enhancing efficiency and precision. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.93 billion by 2026, growing at a CAGR of 6.2%. This growth underscores the significant role that industrial CNC systems play in optimizing production processes across multiple sectors, including aerospace, automotive, and electronics.

With advancements in automation, real-time data analytics, and integration of the Internet of Things (IoT), industrial CNC machines are capable of delivering higher productivity rates and reduced operational costs. As industries increasingly adopt these cutting-edge solutions, the implications for workforce dynamics, supply chain management, and overall competitive advantage become increasingly profound. Thus, understanding the trajectory of industrial CNC technology and its transformative impact on manufacturing efficiency is crucial for stakeholders aiming to stay ahead in a rapidly evolving market.

The Historical Development of CNC Technology in Industrial Manufacturing

The historical development of CNC (Computer Numerical Control) technology marks a significant turning point in industrial manufacturing. Emerging in the 1950s, CNC technology evolved from simple numerical control systems that utilized punched tape to guide machine tools. The introduction of computers revolutionized this process, allowing for more complex designs and improved precision. This advancement laid the groundwork for automated machining, which dramatically reduced human error and increased the speed of production.

By the 1970s and 1980s, the integration of advanced software and user interfaces made CNC technology more accessible to manufacturers. This period saw the rise of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing), which enabled seamless transition from design to production. As CNC machines became more versatile, industries like automotive, aerospace, and medical manufacturing adopted them widely, leading to significant improvements in manufacturing efficiency, flexibility, and scalability. The continuous evolution of CNC technology has not only optimized traditional manufacturing but also paved the way for innovations like additive manufacturing and Industry 4.0, further transforming the landscape of industrial production.

The Evolution of Industrial CNC Technology

This bar chart illustrates the evolving adoption rates of CNC technology in industrial manufacturing from the 1970s to the 2020s. The data indicates a significant increase in adoption, reflecting the technological advancements and the impact on manufacturing efficiency.

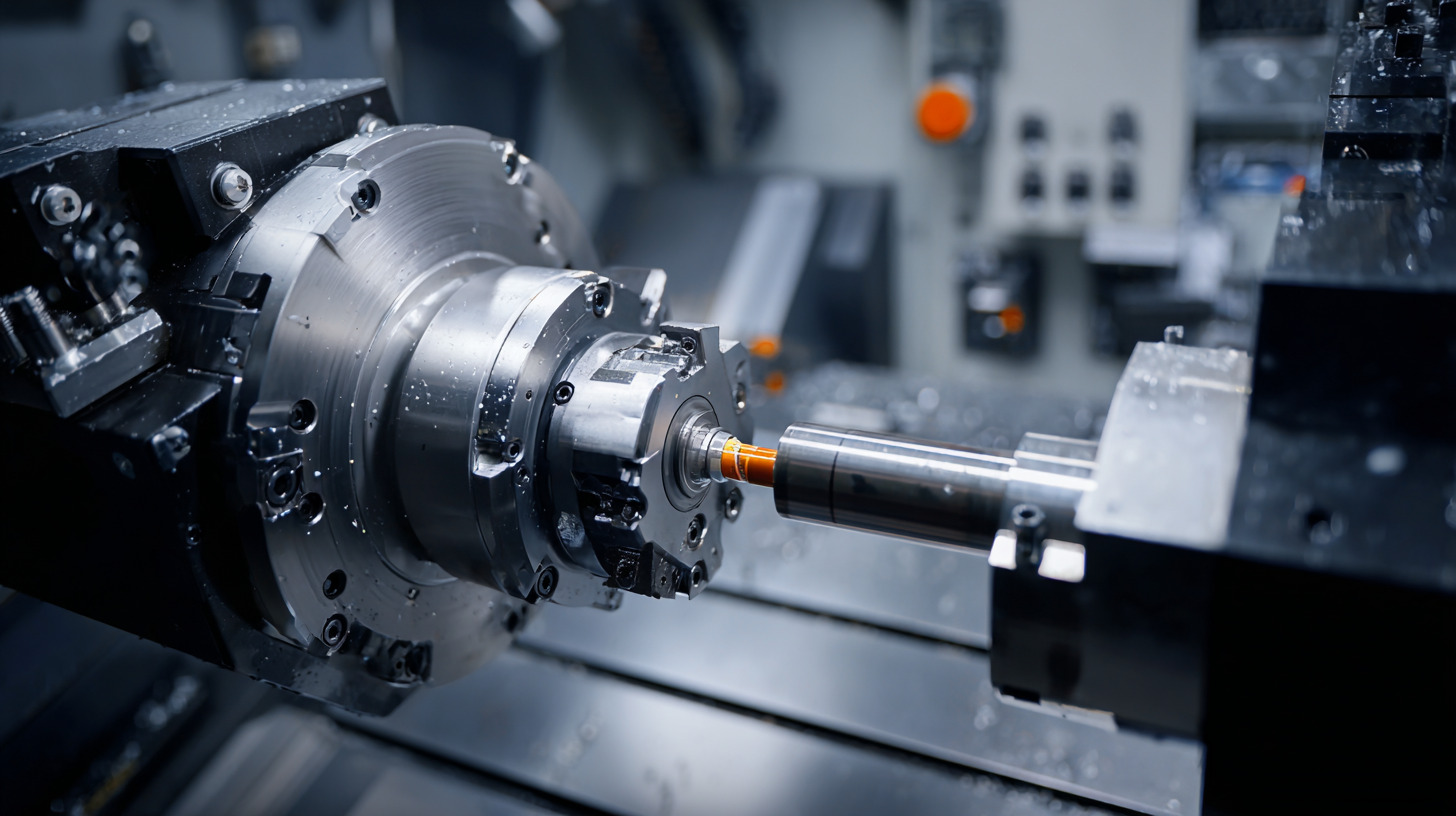

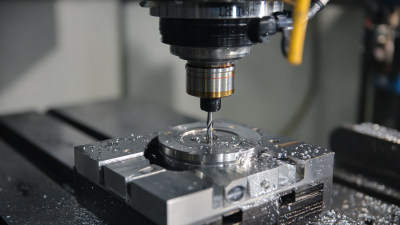

Key Innovations that Shaped CNC Machinery and Their Functionality

The landscape of CNC technology has undergone significant transformations over the years, largely driven by innovations that enhance functionality and efficiency in manufacturing processes. Key advancements such as high-speed machining, multi-axis capabilities, and automation integration have revolutionized how manufacturers approach production. With the global CNC machine market projected to expand from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a robust CAGR of 9.9%, the implications of these innovations are profound.

Critical innovations include the development of advanced CNC controllers and software solutions that facilitate real-time monitoring and optimization of machining operations. These technologies not only improve precision but also reduce downtime, ultimately leading to higher throughput. Companies specializing in CNC simulation and verification have played a pivotal role in advancing these tools, making it possible for manufacturers to predict and solve potential machining issues before they arise. As the industry continues to embrace cutting-edge technologies, the impact on manufacturing efficiency will only become more pronounced, highlighting the importance of ongoing innovation in CNC machinery design and functionality.

The Evolution of Industrial CNC Technology and Its Impact on Manufacturing Efficiency

| Year | Innovation | Impact on Efficiency | Key Feature |

|---|---|---|---|

| 1952 | Introduction of CNC Machines | Increased automation reduced manual errors | Numerical control programming |

| 1980s | Integration of CAD/CAM | Streamlined design to manufacturing process | Seamless data transfer |

| 1990s | Advent of PLCs in CNC | Enhanced control over manufacturing processes | Programmable logic control |

| 2000s | Development of High-Speed CNC | Significantly decreased cycle times | High-speed spindle technology |

| 2010s | Adoption of cloud technology | Enhanced data management and remote access | Cloud-based software solutions |

| 2020s | AI and Machine Learning Integration | Optimized machining processes through predictive analysis | Real-time decision-making tools |

Effects of CNC Technology on Production Speed and Precision

CNC (Computer Numerical Control) technology has revolutionized the manufacturing landscape by significantly enhancing production speed and precision. One of the most notable effects is the ability to automate complex machining processes, which reduces human error and minimizes production downtime. With CNC machines, manufacturers can produce intricate parts with consistent quality, ensuring that each item meets strict dimensional tolerances. This automation allows for uninterrupted operation, enabling companies to ramp up production without compromising on accuracy.

CNC (Computer Numerical Control) technology has revolutionized the manufacturing landscape by significantly enhancing production speed and precision. One of the most notable effects is the ability to automate complex machining processes, which reduces human error and minimizes production downtime. With CNC machines, manufacturers can produce intricate parts with consistent quality, ensuring that each item meets strict dimensional tolerances. This automation allows for uninterrupted operation, enabling companies to ramp up production without compromising on accuracy.

Moreover, the integration of advanced CNC technology facilitates rapid prototyping and flexible manufacturing. This adaptability means that changes in design or production specifications can be implemented swiftly without the need for extensive retooling. The result is a more agile manufacturing process that can respond quickly to market demands. Businesses utilizing CNC systems experience a faster turnaround time, which not only boosts productivity but also enhances competitive advantage in an increasingly dynamic marketplace.

As CNC technology continues to evolve, its positive effects on production speed and precision remain pivotal for manufacturers aiming for operational excellence.

Integration of CNC Systems with Modern Automation Techniques

The integration of CNC (Computer Numerical Control) systems with modern automation techniques is revolutionizing the manufacturing landscape. By combining CNC technology with robotics and IoT (Internet of Things), manufacturers are achieving unprecedented levels of precision, flexibility, and efficiency. Automated CNC machines can now communicate with each other and adjust settings in real-time, allowing for optimized production processes that minimize downtime and waste.

Tips: To enhance the efficiency of CNC operations, consider implementing a centralized monitoring system that tracks machine performance. This enables proactive maintenance, reducing the likelihood of unexpected breakdowns. Additionally, investing in advanced software solutions can streamline workflow and improve design-to-production cycles.

The marriage of CNC technology with automation not only boosts productivity but also enhances the ability to customize products. Manufacturers can swiftly adapt to changing consumer demands without sacrificing quality or consistency. This agility is crucial in today’s fast-paced market, where the ability to innovate quickly can set a company apart from its competitors.

Tips: Train your staff on the latest CNC programming techniques and automation tools. This ensures your team can fully utilize the new technology and maintain a competitive edge in the ever-evolving manufacturing sector.

Future Trends in CNC Technology and Their Potential Impact on Efficiency

As the landscape of manufacturing evolves, the CNC (Computer Numerical Control) technology continues to advance, leading to significant efficiency improvements. Future trends indicate a surge in the adoption of automation and artificial intelligence (AI) within CNC systems. According to a report by MarketsandMarkets, the global CNC market is projected to reach $100 billion by 2025, driven by increasing demand for precision and productivity in manufacturing processes. This growth highlights the potential for smart CNC machines to optimize production lines through real-time data analytics and predictive maintenance.

Another emerging trend is the integration of IoT (Internet of Things) in CNC operations. A study by Grand View Research forecasts a remarkable 25% compound annual growth rate (CAGR) in the adoption of intelligent manufacturing technologies over the next five years. By connecting CNC machines to a centralized network, manufacturers can achieve better operational insights and reduce downtime, ultimately enhancing efficiency.

Tip: Consider incorporating smart sensors into your CNC systems to gather data that can pinpoint inefficiencies and improve overall productivity.

Furthermore, the development of additive manufacturing techniques, combined with traditional CNC machining, offers a pathway for hybrid production environments, where speed and customization meet quality. This synergy not only elevates manufacturing capabilities but also positions companies to respond swiftly to market demands.

Tip: Stay updated on advancements in CNC technology to identify the best solutions for your specific manufacturing challenges, maximizing both productivity and competitiveness.

Related Posts

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

Why Investing in CNC Machines Can Boost Your Production Efficiency by 30% Financially

-

Understanding Global Manufacturing Standards for Best CNC Milling Processes

-

Navigating Import Export Certifications for Best CNC Metal Products with Practical How to Strategies

-

Exploring the Unique Features and Applications of Various CNC Router Machine Alternatives

-

2025 Market Insights: How to Choose the Best CNC Engraver for Your Business Needs

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information