Ultimate Guide to Choosing the Best CNC Engraving Machine for Your Business Needs

In today's competitive manufacturing landscape, investing in a CNC engraving machine has become increasingly essential for businesses aiming to enhance precision and efficiency in their production processes. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100.29 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.07% from 2021 to 2026. This trend underscores the growing need for advanced machinery that can provide intricate and detailed engraving capabilities, making it crucial for business owners to choose the right CNC engraving machine tailored to their specific needs. This ultimate guide presents a comprehensive checklist to help you make an informed decision, ensuring that your investment aligns with your operational goals and market demands. Whether you are involved in metalworking, woodworking, or other industries, selecting the right CNC engraving machine can significantly impact your productivity and product quality.

Understanding CNC Engraving Machines: Types and Their Applications in Modern Industry

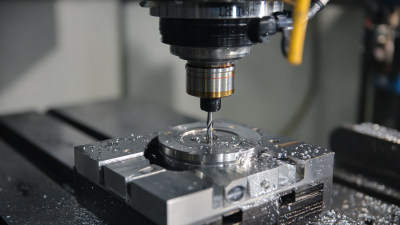

CNC engraving machines have revolutionized the manufacturing industry by offering precision and versatility in creating intricate designs. There are several types of CNC engraving machines available, each tailored to specific applications. For instance, rotary engraving machines are ideal for creating three-dimensional designs on various materials, including metal and wood.

Their ability to carve deep into surfaces makes them a favorite among jewelry manufacturers and sign makers.

On the other hand, laser engraving machines utilize high-powered lasers to etch designs with incredible detail on a wide range of materials, from glass to plastic. This technology is particularly valued in industries such as aerospace and automotive, where precision and accuracy are paramount.

CNC routers also play a critical role in large-scale production, as they can handle bigger workpieces and are perfect for cutting and engraving on materials like MDF and plywood. By understanding the different types and their applications, businesses can make informed choices that align with their production needs.

Key Factors to Consider When Choosing a CNC Engraving Machine for Business Efficiency

When selecting a CNC engraving machine for business efficiency, several key factors must be carefully evaluated. One of the most significant considerations is the specific needs of your business, which can vary based on the materials you work with and the complexity of the designs you intend to create. For instance, the global industrial lasers market is anticipated to grow from $23.90 billion in 2025 to a staggering $55.09 billion by 2032, indicating a rising demand for advanced engraving solutions. This growth highlights the importance of investing in technology that not only meets current requirements but also has the potential to adapt to future demands.

Moreover, automation features are increasingly becoming a necessity in modern CNC machines. As reported, the computer numerical control (CNC) market continues to expand, with an outlook suggesting an increasing integration of smart technologies in machine tools. Businesses should focus on machines that offer enhanced automation for improved production efficiency and precision. As leading manufacturers unveil innovations, such as upgraded laser tools with class-leading safety ratings and advanced capabilities for metal engraving, evaluating these features ensures that your chosen equipment aligns with industry advancements and will bolster your operations.

Analyzing Cost vs. Benefit in CNC Engraving Machine Investments: What the Data Reveals

When evaluating the investment in a CNC engraving machine for your business, it is crucial to analyze the cost versus benefit in detail. The CNC machine tools market is projected to grow significantly, with an estimated compound annual growth rate (CAGR) of over $10.3%, potentially exceeding USD 161.27 billion by 2032. This robust growth can directly impact your decision-making, as investing in a reliable CNC engraving machine is likely to yield substantial returns, particularly as demand for customized and intricate designs continues to rise.

Furthermore, understanding the market dynamics is essential. For instance, while the CNC metal cutting machine tools market is expected to reach USD 252.67 billion by 2034, entities are increasingly drawn to the capabilities of CNC engraving machines that offer precision and efficiency. The ability to produce intricate designs quickly not only enhances productivity but also gives businesses a competitive edge in meeting diverse customer demands. Thus, during your evaluation, consider how the integration of advanced CNC technology can significantly affect your operational capabilities and overall profitability in the long run.

Safety Features and Compliance: Ensuring Your CNC Engraving Machine Meets Industry Standards

When selecting a CNC engraving machine for your business, prioritizing safety features and compliance with industry standards is crucial. The incorporation of emergency stop systems (e-stops) is a fundamental aspect, as these systems help ensure operator safety during unexpected situations. Recent developments allow for wireless and remote e-stops, but manufacturers must adhere to strict guidelines regarding their design and placement. Ensuring that your CNC machine complies with these regulations not only enhances safety but also fosters trust with your workforce.

Moreover, navigating compliance requirements extends beyond immediate safety features. In regions like Great Britain, the Supply of Machinery (Safety) Regulations 2008 outlines essential criteria that machinery must meet before being marketed or put into service. Staying informed about these regulations, including mandatory certifications like the China Compulsory Certificate Self-Declaration, can prevent costly delays and ensure that your operations run smoothly. As the market for various cutting technologies, including glass and laser cutting machines, continues to grow, compliance becomes increasingly vital for businesses to thrive in a competitive landscape.

The Impact of Automation on CNC Engraving: Enhancing Productivity and Precision for Competitive Edge

Automation has revolutionized the CNC engraving industry, significantly enhancing productivity and precision. By integrating advanced automation technologies, businesses can streamline their engraving processes, reducing the need for manual intervention. This not only accelerates production times but also minimizes the risk of human error, resulting in more consistent and accurate engravings. As a result, companies can boost their output without sacrificing quality, allowing them to meet growing demand efficiently.

Moreover, the implementation of automated CNC engraving machines has given businesses a competitive edge in the market. With features like automatic tool changes, on-the-fly adjustments, and precise software controls, companies can easily adapt to diverse engraving needs. This versatility enables them to take on various projects, from intricate designs to large-scale production runs, making their services appealing to a broader customer base. Ultimately, the strategic use of automation in CNC engraving not only positions businesses for success but also fosters innovation in design and manufacturing processes.

Ultimate Guide to Choosing the Best CNC Engraving Machine for Your Business Needs

| Machine Type | Max Engraving Area (mm) | Speed (mm/min) | Precision (mm) | Automation Features | Price Range (USD) |

|---|---|---|---|---|---|

| Desktop CNC Engraver | 300 x 200 | 1000 | 0.01 | Basic | 500 - 1500 |

| Industrial CNC Engraver | 1000 x 600 | 3000 | 0.005 | Advanced | 5000 - 15000 |

| Laser CNC Engraver | 600 x 400 | 2000 | 0.01 | Optical Auto-Focus | 3000 - 8000 |

| Mini CNC Engraver | 200 x 200 | 1500 | 0.02 | Manual | 300 - 800 |

| CNC Router Engraver | 1500 x 900 | 5000 | 0.03 | Semi-Automatic | 4000 - 12000 |

Related Posts

-

2025 Market Insights: How to Choose the Best CNC Engraver for Your Business Needs

-

Navigating Global Trade Standards for Best Desktop CNC Machine Import and Export

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

Understanding Global Manufacturing Standards for Best CNC Milling Processes

-

Future Trends in Global CNC Machinery Market Leading to the Best Home CNC Machine of 2025

-

Unlocking Creative Manufacturing with Best Desktop CNC Applications and How to Get Started

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information