Why Investing in CNC Machines Can Boost Your Production Efficiency by 30% Financially

In today’s competitive manufacturing environment, enhancing production efficiency is paramount for businesses aiming to stay ahead. One significant method to achieve this is by investing in CNC machines, which are vital tools that combine precision and speed in the production process. By integrating advanced CNC technology, companies can enhance their operational capabilities, streamline workflows, and significantly reduce downtime. Research shows that implementing CNC machines can boost production efficiency by up to 30%, leading to both increased output and cost savings.

This article delves into the financial benefits associated with CNC machine investments, exploring how these machines not only improve product quality but also enable manufacturers to meet growing market demands with ease. Understanding the advantages of CNC machines can help businesses make informed decisions that drive long-term growth and sustainability.

Understanding the Basics of CNC Machines and Their Functionality

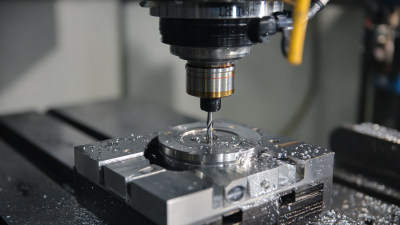

CNC machines, or Computer Numerical Control machines, represent a significant advancement in manufacturing technology. They operate using programmed software to control the movement of tools and machinery, allowing for precise cuts and designs with minimal human intervention. By using a digital blueprint, CNC machines can produce complex shapes and patterns that are difficult to achieve manually. This automation not only enhances precision but substantially reduces the margin of error, making CNC machines essential in industries such as aerospace, automotive, and metalworking.

CNC machines, or Computer Numerical Control machines, represent a significant advancement in manufacturing technology. They operate using programmed software to control the movement of tools and machinery, allowing for precise cuts and designs with minimal human intervention. By using a digital blueprint, CNC machines can produce complex shapes and patterns that are difficult to achieve manually. This automation not only enhances precision but substantially reduces the margin of error, making CNC machines essential in industries such as aerospace, automotive, and metalworking.

Understanding the functionality of CNC machines is crucial for any manufacturer looking to optimize production efficiency. These machines can perform a variety of tasks, including milling, turning, and drilling, all of which can be programmed to execute multiple operations in one setup. This minimizes downtime and maximizes throughput, contributing to improved productivity. Furthermore, the ability to replicate designs consistently means companies can maintain quality standards while scaling production. As a result, investing in CNC technology can be a strategic move that boosts overall operational efficiency, leading to significant financial benefits.

Assessing Your Production Needs: When to Invest in CNC Technology

When considering the enhancement of your production efficiency, assessing your production needs is crucial before diving into the investment in CNC (Computer Numerical Control) machines. Start by identifying the specific areas where inefficiencies occur. Are you facing bottlenecks in production or limitations in precision and repeatability? Understanding these pain points can provide clarity on whether CNC technology aligns with your goals.

**Tips for Assessing Production Needs:**

1. **Evaluate Current Processes:** Take time to analyze existing workflows. Identify tasks that are time-consuming and prone to errors. This assessment will help you pinpoint opportunities where CNC machines can make a significant impact.

2. **Factor in Scalability:** Consider not only current production demands but also future growth. Smart investments in CNC machines can accommodate increased demand and complexity without requiring a proportional increase in labor or time.

3. **Cost-Benefit Analysis:** Weigh the upfront costs of CNC technology against potential savings and efficiency gains. Calculate the return on investment by estimating both short-term and long-term benefits, including labor cost reductions and improved product quality.

By thoroughly assessing your production needs, you can make informed decisions regarding CNC investments that ultimately enhance efficiency and profitability.

Impact of CNC Machine Investment on Production Efficiency

Calculating the Financial Return on Investment from CNC Machines

Investing in CNC machines offers a compelling return on investment (ROI) that can significantly enhance production efficiency. According to a report by the International Federation of Robotics, companies that integrate CNC technology can see a productivity increase of up to 30%. This efficiency gain translates into shorter production cycles and lower operational costs, allowing manufacturers to remain competitive in rapidly evolving markets.

When calculating the financial ROI from CNC machines, it’s crucial to consider both direct and indirect benefits. Directly, CNC machines reduce labor costs and material waste, as they provide precision and consistency that manual machines simply cannot achieve. Indirectly, the enhanced production capabilities can lead to increased customer satisfaction due to improved product quality and faster delivery times. A study from the National Association of Manufacturers suggests that 80% of manufacturers report a significant rise in fulfillment accuracy with CNC machining, thereby driving repeat business.

**Tip:** To maximize your CNC investment, regularly maintain your machines to avoid downtime. Scheduled maintenance can preempt costly repairs and keep production running smoothly.

**Tip:** Another smart strategy is to invest in employee training on CNC systems. Skilled operators can further enhance the machine's capabilities, leading to even greater efficiency and productivity.

Why Investing in CNC Machines Can Boost Your Production Efficiency by 30% Financially

| Dimension | Before CNC Investment | After CNC Investment | % Change |

|---|---|---|---|

| Production Output (units/day) | 100 | 130 | 30% |

| Labor Costs ($/day) | 500 | 450 | -10% |

| Material Waste (%) | 15% | 10% | -33.33% |

| Overall Production Time (hours/week) | 40 | 28 | -30% |

| Total Revenue ($) | 10,000 | 13,000 | 30% |

Implementing CNC Machines: Steps for Maximizing Production Efficiency

Implementing CNC machines is a strategic approach to enhancing production efficiency in various industries, including woodworking and furniture manufacturing. The transition to CNC technology can lead to a remarkable boost in productivity, potentially increasing output by up to 30%. The key to maximizing production efficiency lies in understanding how to effectively integrate these machines into your existing operations.

To begin, it's crucial to assess your current production processes and identify areas where CNC machines can offer significant improvements. Training your workforce on CNC technology will ensure they can operate and maintain the machines effectively, reducing downtime and enhancing the productivity of your production line. Additionally, investing in robust software tools that complement CNC operations can streamline workflow and further elevate efficiency.

Tips for success include setting clear goals for what you want to achieve with CNC integration, conducting regular maintenance to prevent breakdowns, and continuously evaluating your production metrics to adjust your strategies. By fostering a culture of adaptability and continuous improvement, businesses can fully leverage the advantages that CNC machines provide, ultimately driving profitability and growth.

Maintenance and Best Practices to Sustain CNC Machine Performance

Investing in CNC machines not only enhances production capabilities but also requires a steadfast commitment to maintenance and best practices to sustain their performance. A recent study by the American Machinist revealed that optimized maintenance schedules can reduce operational downtime by up to 20%, significantly impacting overall production efficiency. Implementing predictive maintenance strategies, such as utilizing IoT technology to monitor machine health in real-time, can further increase machine uptime, leading to an estimated 30% boost in production output, translating into substantial financial gains.

Incorporating best practices such as routine inspections, tool calibration, and employee training can also prolong the lifespan of CNC machines. According to a report from the National Institute of Standards and Technology (NIST), manufacturers that adhere to rigorous maintenance protocols experience a 15% reduction in maintenance costs. By ensuring that CNC machines are calibrated correctly and regularly serviced, manufacturers can avoid costly interruptions and optimize their resources, thus maintaining a competitive edge in the fast-evolving market landscape.

Related Posts

-

The Ultimate Guide to Maximizing Efficiency with Industrial CNC Machines

-

Understanding Global Manufacturing Standards for Best CNC Milling Processes

-

Navigating Import Export Certifications for Best CNC Metal Products with Practical How to Strategies

-

Exploring the Unique Features and Applications of Various CNC Router Machine Alternatives

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

Exploring the Features and Applications of the Best CNC Milling Machines for Every Industry

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information