The Ultimate Guide to Maximizing Efficiency with Industrial CNC Machines

In today's rapidly evolving manufacturing landscape, the significance of utilizing industrial CNC machines cannot be overstated. A comprehensive report from the International Federation of Robotics highlights that the adoption of CNC machining technology has increased manufacturing efficiency by up to 30%, significantly reducing production lead times and operational costs. As industries strive for competitiveness and precision, the capabilities of industrial CNC machines to perform complex tasks with remarkable accuracy make them indispensable. Moreover, a survey conducted by the Machine Tool Technology Association revealed that nearly 70% of manufacturers are investing in advanced CNC systems to enhance their production processes. This guide aims to delve into the strategies and best practices for maximizing efficiency with industrial CNC machines, ensuring that businesses not only meet the market demands but also excel in their operational performance.

Understanding the Basics of Industrial CNC Machines and Their Types

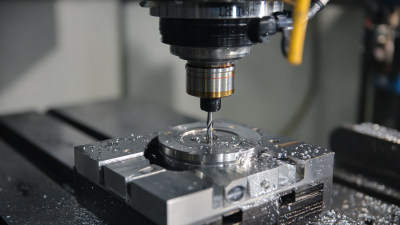

Understanding the basics of industrial CNC (Computer Numerical Control) machines is essential for maximizing efficiency in manufacturing processes. CNC machines are automated tools that use precise programming to control their operation, making them invaluable in industries such as automotive, aerospace, and electronics. There are several types of CNC machines, each tailored to specific tasks. Common types include CNC milling machines, CNC lathes, CNC plasma cutters, and CNC routers, each offering unique advantages based on the materials and intricacies of the projects involved.

CNC milling machines, for example, are designed for cutting and shaping materials with high precision using rotary cutters. They are ideal for creating complex geometries and can work with various materials, including metals, plastics, and wood. On the other hand, CNC lathes excel in producing symmetrical parts, where rotation and cutting can create cylindrical shapes effectively. Understanding these differences helps businesses select the proper CNC machine for their needs, ultimately enhancing productivity and reducing waste in production cycles. By familiarizing oneself with these machines and their functionalities, manufacturers can optimize their operations to achieve higher efficiency and output.

Key Types of CNC Machines and Their Applications in Various Industries

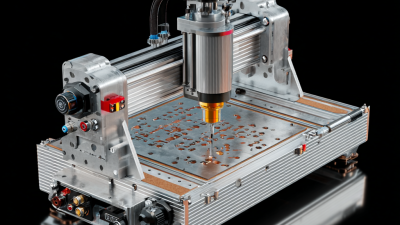

The adoption of CNC (Computer Numerical Control) machines has revolutionized manufacturing across various industries, driving significant productivity gains. These machines use computer programming to automate processes, ensuring precise and repeatable output. Key types of CNC machines, such as milling machines, lathes, and laser cutters, serve different applications. For instance, milling machines are ideal for shaping materials, while laser cutters excel in detailed etching and engraving. Each type plays a crucial role in sectors ranging from aerospace to automotive, enabling manufacturers to meet high-quality standards while minimizing waste.

With the CNC machines market projected to reach USD 170.4 billion by 2033, growing at a CAGR of 9.80%, the influence of these technologies will only expand. As industries become more competitive, integrating CNC machines into production lines helps businesses enhance efficiency and reduce turnaround times. Furthermore, the rising demand for high torque stepper motors, expected to surpass USD 1.94 billion by 2034, highlights the crucial role of precision control in improving the performance of CNC machines, ultimately paving the way for smarter and more adaptable manufacturing processes.

The Ultimate Guide to Maximizing Efficiency with Industrial CNC Machines

This chart illustrates the various types of industrial CNC machines and their applications across different industries. The data reflects the distribution of usage percentages among key types of CNC machines: CNC Milling, CNC Turning, CNC Laser Cutting, and CNC Plasma Cutting.

Comparative Analysis of CNC Machine Tools: Pros and Cons

When evaluating CNC machine tools for industrial efficiency, a comprehensive comparative analysis of their pros and cons is essential. For instance, vertical machining centers (VMCs) offer significant advantages in terms of versatility and precision. According to a report by IBISWorld, the global CNC machining market size reached approximately $65 billion in 2022, driven in part by the increasing adoption of VMCs across various sectors. Their ability to handle complex geometries and produce high-quality finishes makes them a go-to choice for manufacturers seeking to enhance production capabilities.

On the other hand, horizontal machining centers (HMCs) also present their own set of benefits and limitations. They excel in high-volume production and are known for their efficient chip removal processes, resulting in less downtime. However, the initial investment and footprint can be considerable drawbacks. According to a study by Grand View Research, HMCs can lead to a 40% increase in production efficiency compared to VMCs, but they require a workforce skilled in programming and maintenance, which can pose a challenge for smaller operations. Thus, understanding the trade-offs between these machines is crucial in making informed decisions tailored to specific production needs.

The Ultimate Guide to Maximizing Efficiency with Industrial CNC Machines

| CNC Machine Type | Pros | Cons | Ideal Applications | Average Cost ($) |

|---|---|---|---|---|

| CNC Milling Machine | Versatile, high precision | Requires skilled operators | Metal parts, prototypes | $40,000 - $150,000 |

| CNC Lathe | High accuracy, efficient for round parts | Limited to rotational parts | Shafts, axles | $25,000 - $100,000 |

| CNC Laser Cutter | Clean cuts, no tool wear | Material limitations, high energy usage | Sheet metal, plastics | $30,000 - $200,000 |

| CNC Plasma Cutter | Fast cutting speed, good for thick materials | Limited to conductive materials | Steel, aluminum | $20,000 - $100,000 |

| CNC Waterjet Cutter | Cuts a wide range of materials, minimal heat | Slower than laser, higher operational costs | Stone, glass, metals | $50,000 - $300,000 |

Integrating Automation for Enhanced CNC Efficiency and Productivity

In today’s rapidly evolving manufacturing landscape, the integration of automation is becoming essential for enhancing the efficiency and productivity of CNC (Computer Numerical Control) machines. Recent reports indicate that the industrial automation market is projected to reach $300 billion by 2026, highlighting a significant investment in technologies that streamline and optimize production processes. Companies are increasingly embracing solutions that connect their CNC machines with advanced technologies, such as AI and IoT, to ensure seamless operations and minimize downtime.

The adoption of automated production lines has proven to boost operational efficiency by up to 30%, particularly in additive manufacturing and CNC processes. Automation technologies, including collaborative robots and digital twin systems, are transforming traditional manufacturing models, enabling more flexible, precise, and efficient workflows. As industries move towards data-driven decision-making, integrating these advanced systems is not merely an option but a necessity for staying competitive. Research suggests that firms implementing smart manufacturing solutions can reduce operational costs by 20% while significantly improving product quality and turnaround times.

Best Practices for Maintenance and Operation of CNC Machines

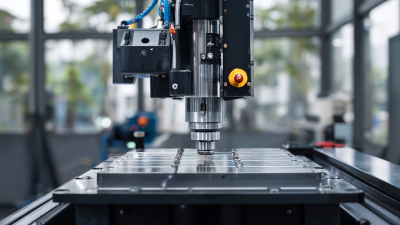

Maintaining and operating CNC machines efficiently is crucial for industries looking to optimize productivity and minimize downtime. Regular maintenance practices, such as routine inspections and timely replacement of worn-out parts, can significantly extend the lifespan of these machines. According to industry reports, the CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9% during this period. This growth highlights the increasing reliance on CNC technology, making it essential for operators to implement best practices in machine maintenance and operation.

One of the vital aspects of maximizing efficiency is adopting a preventive maintenance schedule that addresses potential issues before they escalate. Incorporating digital monitoring tools can help track machine performance in real-time, allowing for immediate attention to irregularities. Furthermore, ensuring that operators are adequately trained on machine functionalities and safety protocols can lead to more efficient operations and reduced risk of costly errors. As the CNC industry evolves, keeping abreast of technological advancements and integrating them into daily operations will be key to maintaining a competitive edge.

Related Posts

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

Understanding Global Manufacturing Standards for Best CNC Milling Processes

-

Navigating Import Export Certifications for Best CNC Metal Products with Practical How to Strategies

-

Exploring the Top Alternatives to Best CNC Router Machine for Your Manufacturing Needs

-

Exploring the Unique Features and Applications of Various CNC Router Machine Alternatives

-

Exploring the Features and Applications of the Best CNC Milling Machines for Every Industry

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information