How to Optimize Your DIY CNC Router for Precision and Speed Using Expert Techniques

In today's rapidly evolving manufacturing landscape, the DIY CNC router has emerged as a vital tool for hobbyists and professionals alike, enabling intricate designs with precision. According to a report by Research and Markets, the global CNC machine market is expected to reach $117 billion by 2026, driven by the growing demand for automation and high-precision machinery. Optimizing your DIY CNC router for both precision and speed is essential—not only for achieving superior results but also for enhancing productivity. Techniques such as fine-tuning the router speed, adjusting feed rates, and implementing advanced software controls can significantly impact performance. As users increasingly seek to push the boundaries of what can be achieved with DIY CNC technology, understanding the expert techniques for enhancement becomes crucial for staying competitive and delivering exceptional outcomes.

Understanding the Basics of CNC Router Mechanics for Enhanced Performance

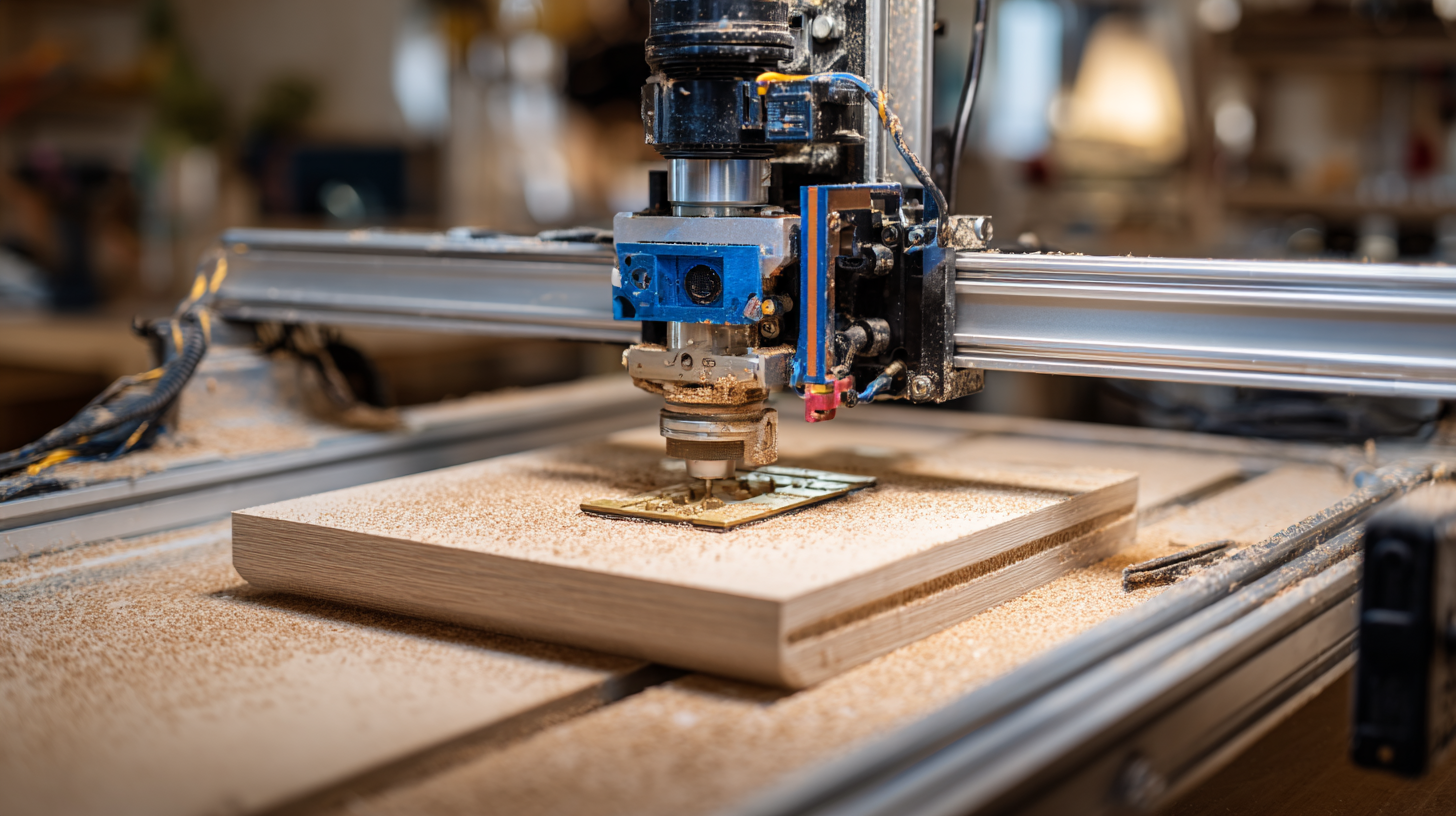

Understanding the mechanics of a CNC router is crucial for anyone looking to maximize its performance. At its core, a CNC router operates by precisely controlling a cutting tool through programmable movements. This involves various components such as the spindle, stepper motors, and guide rails, all of which need to work in harmony. Ensuring that these elements are well-maintained and calibrated can significantly enhance cutting accuracy and overall speed.

Tip 1: Regularly check the alignment of your router's components. Misalignment can lead to uneven cuts and increased wear on the machine. Use a dial indicator to measure and adjust the position of the spindle and rails, ensuring everything aligns perfectly.

Another important aspect is the choice of materials and tooling. Different materials require specific cutting speeds and bit types to achieve optimal results.

Tip 2: Experiment with various feed rates and spindle speeds on scrap material before starting your actual project. Finding the right combination can reduce finishing time while maintaining a fine edge on your cuts.

By grasping the fundamentals of CNC router mechanics, you'll not only increase the speed and precision of your cuts but also extend the longevity of your machine.

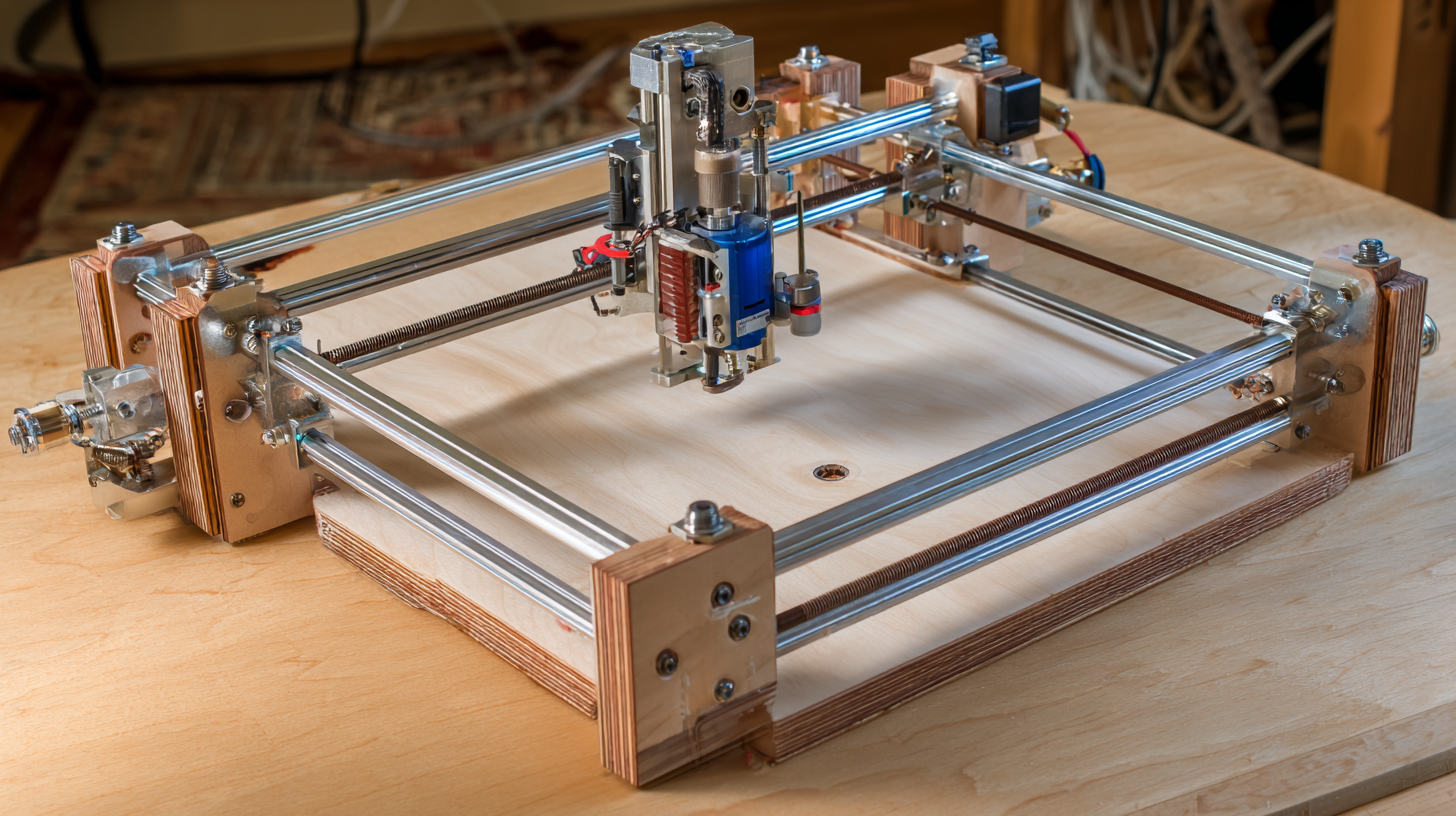

Choosing the Right Components for Improved Precision and Speed in Your CNC Router

Choosing the right components is essential for enhancing the precision and speed of your DIY CNC router. Begin by selecting high-quality linear motion systems, such as precision ball screws or linear rails, which provide smooth and accurate movement. These components minimize backlash and ensure that the router maintains its intended path during operation, crucial for achieving intricate designs with tight tolerances.

Next, consider the motors and drivers you’ll use. Stepper motors are popular for their ease of control and reliability, but if speed is a priority, upgrading to servo motors may be beneficial. Servo systems offer greater torque and responsiveness, allowing your CNC router to execute complex tasks more efficiently. Additionally, incorporating a robust motion controller can greatly optimize performance, enabling advanced features such as acceleration control and automated calibration, which are vital for maintaining both speed and precision throughout the machining process. Overall, careful selection of these components can significantly elevate the capabilities of your CNC router, leading to superior project outcomes.

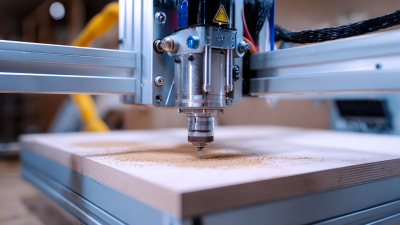

Calibration Techniques to Achieve Maximum Accuracy in DIY CNC Routing

Calibration is crucial to achieving maximum accuracy in DIY CNC routing, allowing hobbyists and professionals alike to harness the full potential of their machines. According to a report from the International Journal of Advanced Manufacturing Technology, precise calibration can enhance cutting accuracy by up to 50%. This improvement is essential for tasks requiring intricate detail, proving beneficial in industries ranging from woodworking to aerospace component manufacturing.

To optimize calibration, it is essential to focus on several key techniques. First, ensure that the gantry and axes are perfectly square. A simple method to check this is the 3-4-5 triangle method, which can be utilized with a tape measure. Additionally, maintaining consistent tension on the belts can help prevent slippage and achieve more stable movements. Regularly checking and adjusting the stepper motor settings to match the machine's specifications can also lead to a reduction in positional errors.

A study by the University of Cambridge highlights that proper motor tuning enhances speed and precision, reducing cycle time by approximately 20% while increasing output quality. By implementing these calibration techniques, users can significantly boost the overall performance of their DIY CNC routers.

Advanced Software Settings to Optimize CNC Routing Efficiency and Output Quality

To achieve ideal efficiency and output quality in your DIY CNC router projects, honing in on advanced software settings is crucial. Begin by refining your toolpath parameters. Adjusting settings such as feed rate and plunge rate can significantly impact the precision and speed of your cuts. For instance, a lower feed rate allows for better detail on intricate designs, while a higher rate can expedite larger operations without sacrificing quality.

**Tips:** Experiment with different speeds in a controlled environment before finalizing your settings. This will help you understand how your specific materials respond and give you the confidence to make adjustments.

Another essential software setting to optimize is the stepper motor settings. Fine-tuning the steps per mm and acceleration can lead to smoother movements and better surface finishes. A proper calibration ensures that the machine doesn't skip steps during operation, which directly affects the overall output quality.

**Tips:** Keep a log of your settings and outcomes. This practice not only aids in replicating successful projects but also provides valuable data for future adjustments and refinements. By meticulously adjusting these advanced software settings, you can significantly elevate the performance of your CNC router.

How to Optimize Your DIY CNC Router for Precision and Speed Using Expert Techniques

| Parameter | Setting Value | Impact on Performance |

|---|---|---|

| Feed Rate | 1200 mm/min | Enhances speed without sacrificing quality |

| Spindle Speed | 8000 RPM | Improves cutting efficiency on harder materials |

| Tool Diameter | 6 mm | Balances precision and cutting speed |

| Material Type | Plywood | Versatile and suitable for a range of projects |

| Stepper Motor Current | 2.5 A | Increases torque, minimizing missed steps |

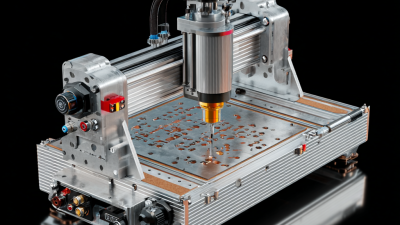

Maintenance Tips for Sustained Precision and Speed in Your CNC Router Operations

Maintaining your DIY CNC router is vital for ensuring sustained precision and speed in your operations. Regular maintenance helps to prevent wear and tear, which can negatively affect the accuracy of your cuts over time. Start by routinely checking and tightening all mechanical connections, including the belts and screws, to avoid any unwanted vibrations that could lead to inaccuracies. Additionally, keep the rails and lead screws clean and well-lubricated to ensure smooth movement; this not only enhances performance but also prolongs the life of these components.

Another key aspect of maintenance involves the proper calibration of your CNC router. Periodically recalibrate your machine to ensure that it is cutting accurately according to the design specifications. This entails checking the squareness of the frame, ensuring the stepper motors are functioning correctly, and verifying that the spindle is properly aligned. Moreover, implementing a regular inspection schedule for your router's software can help identify potential errors or updates needed for optimal performance, allowing you to troubleshoot issues before they impact your work. By establishing a consistent maintenance routine, you can keep your CNC router running efficiently and effectively for years to come.

Optimization of DIY CNC Router Performance

Related Posts

-

Solutions for Optimal CNC Router Kit Performance

-

10 Best Industrial CNC Machines for Maximum Precision in 2023

-

7 Essential Tips for Maximizing Precision with Your Home CNC Machine

-

Unlocking Creative Manufacturing with Best Desktop CNC Applications and How to Get Started

-

Exploring the Future of Best CNC Wood Carving Machines Market Trends and How to Choose the Right One for 2025

-

Exploring the Top Alternatives to Best CNC Router Machine for Your Manufacturing Needs

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information