Top 5 Table Top CNC Machines for Precision Engineering in 2023

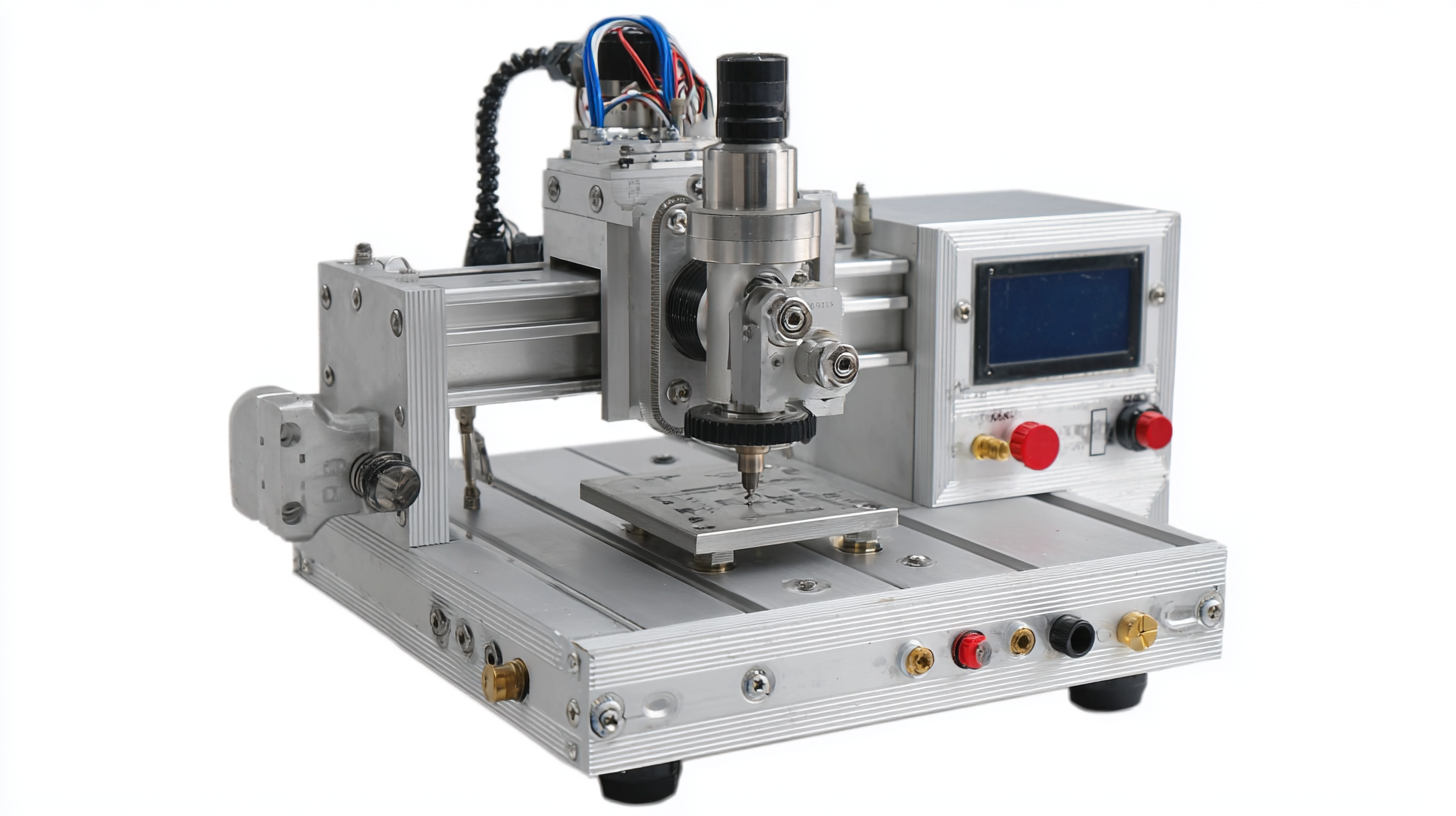

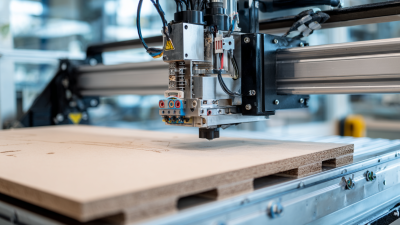

In the rapidly evolving world of precision engineering, table top CNC machines have emerged as indispensable tools for both hobbyists and professionals alike. These compact yet powerful devices offer unparalleled accuracy and versatility, allowing users to transform their creative visions into tangible reality. As 2023 unfurls, the demand for efficient and reliable machining solutions continues to grow, prompting manufacturers to innovate and provide cutting-edge options tailored to fit various needs and budgets.

This article delves into the top five table top CNC machines that are set to dominate the market in 2023. We will explore their key features, capabilities, and how they can enhance precision engineering projects. Whether you are a seasoned machinist or a newcomer looking to delve into the world of CNC machining, understanding the available options is crucial for making an informed decision. The right table top CNC machine can unlock new possibilities in design, complexity, and craftsmanship, paving the way for exceptional results in any workshop setting. Join us as we uncover the best choices that stand out in this competitive landscape.

Top Features to Look for in a Table Top CNC Machine for Precision Engineering

When selecting a table top CNC machine for precision engineering in 2023, there are several key features that should be considered. First and foremost is the machine’s accuracy and repeatability; these factors are critical for ensuring that each component meets strict tolerances. According to the CNC Machine Tool Market Report, machines with a resolution of 0.001 mm or better are becoming increasingly common, enabling engineers to achieve higher precision in their designs.

Another important aspect is the build quality and rigidity of the machine. A sturdy frame minimizes vibrations during operation, which can lead to improved finish quality and longer tool life. Research indicates that CNC machines with a heavier construction can reduce errors caused by flexing, thus optimizing the overall workflow and productivity by up to 20%. Additionally, integrated software features that allow for easy programming and real-time adjustments can significantly enhance user experience and efficiency. Modern machines often come equipped with user-friendly interfaces and advanced CAD/CAM software compatibility, which is crucial for streamlining the design and production process in precision engineering projects.

Comparing the Best Models: Performance and Value in 2023

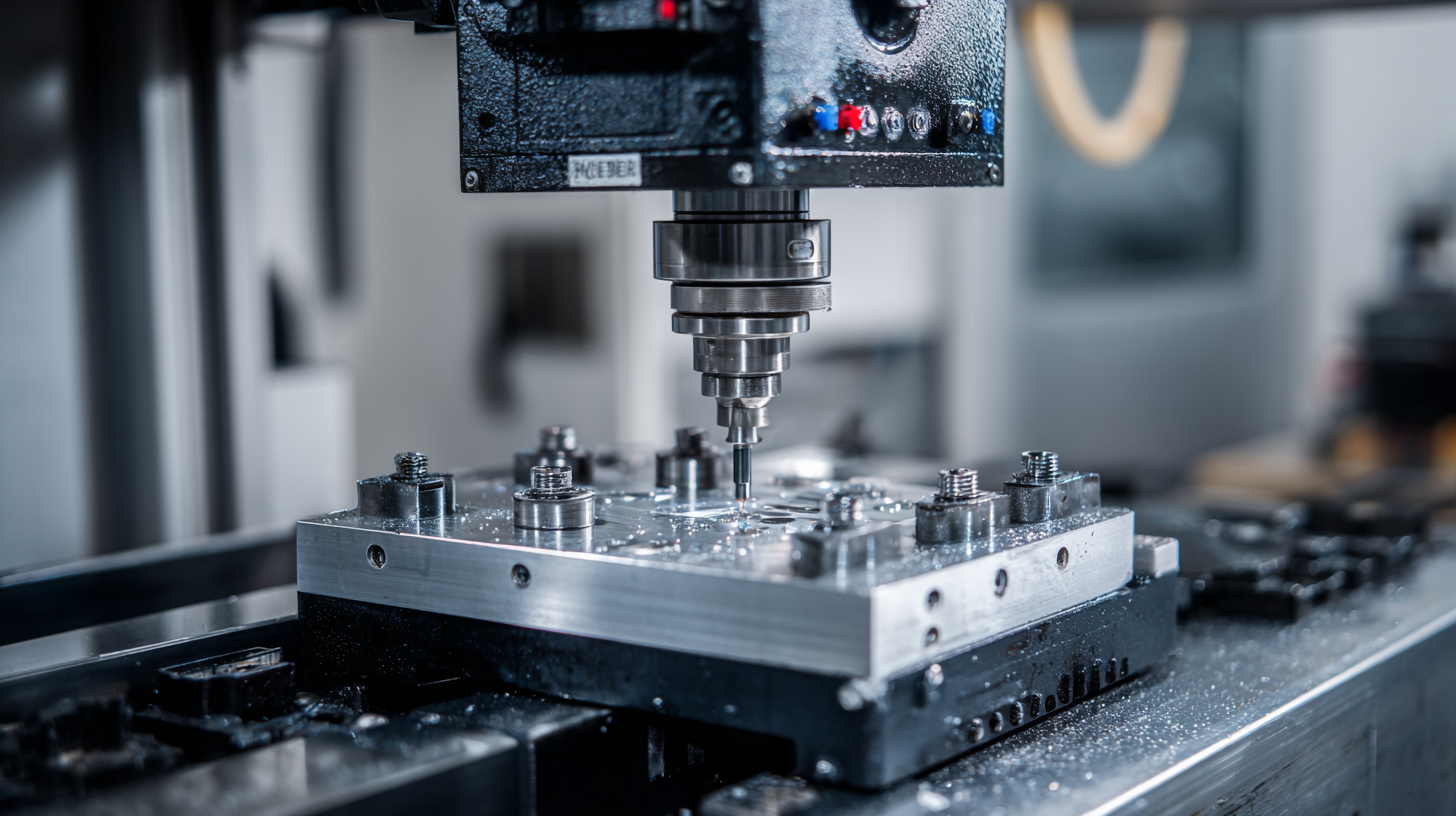

In 2023, the market for tabletop CNC machines has evolved significantly, emphasizing precision engineering and versatile applications. When comparing top models, it's vital to consider their performance metrics and overall value. Reports indicate that CNC machines designed for hobbyists and small businesses have shown an average accuracy within 0.002 inches, which is crucial for intricate projects in industries such as jewelry making and prototyping. The most exceptional machines combine robust build quality with features like automatic tool changers and advanced software compatibility, enhancing user experience and productivity.

Tip: Always assess the total cost of ownership when selecting a CNC machine. While some models may have a lower initial price, factors such as maintenance costs, software updates, and tool replacements can significantly affect your long-term investment.

Additionally, many of these machines now come equipped with user-friendly interfaces and extensive online support communities, providing essential resources for both beginners and experienced users. Data from industry analysts suggest that machines with strong community engagement can boost user confidence and reduce operational setbacks.

Tip: Consider joining online forums or local CNC user groups to share experiences and gain insights on best practices, which can further enhance your operational efficiency.

Top 5 Table Top CNC Machines for Precision Engineering in 2023

| Model | Max Spindle Speed (RPM) | Work Area (mm) | Precision (μm) | Price ($) |

|---|---|---|---|---|

| CNC Machine A | 24000 | 300 x 200 x 150 | 10 | 1500 |

| CNC Machine B | 20000 | 400 x 300 x 200 | 8 | 2300 |

| CNC Machine C | 18000 | 250 x 250 x 150 | 12 | 1200 |

| CNC Machine D | 30000 | 500 x 400 x 300 | 9 | 2900 |

| CNC Machine E | 22000 | 350 x 250 x 200 | 11 | 1700 |

Expert Tips for Maximizing Efficiency with CNC Machines

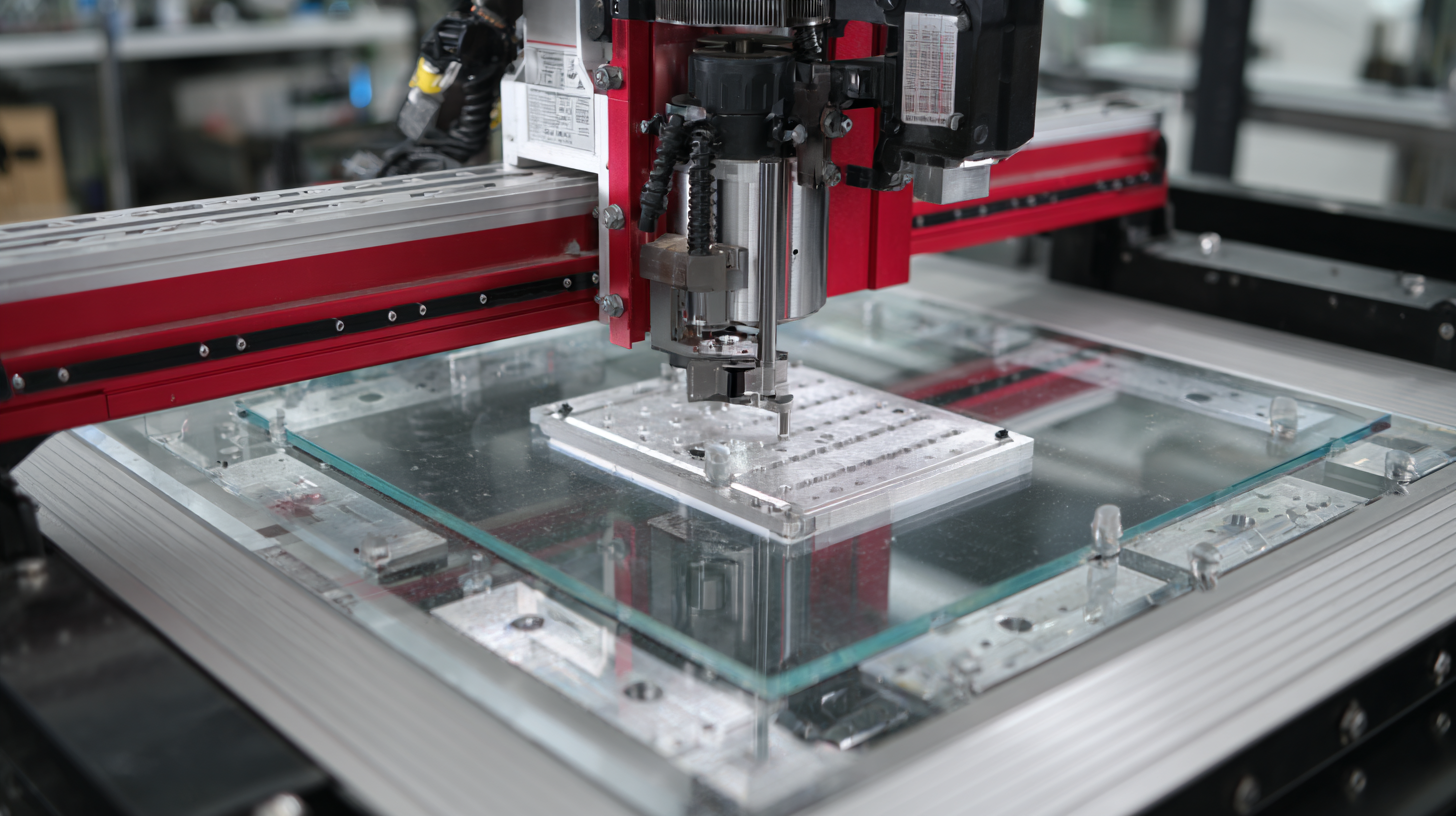

In the world of precision engineering, maximizing the efficiency of CNC machines is crucial for achieving optimal results. According to a report by Technavio, the global CNC machine market is expected to grow by over $3 billion from 2021 to 2025, underscoring the importance of effective operation in an increasingly competitive environment. To help you get the most out of your tabletop CNC machine, here are some expert tips.

Firstly, proper maintenance is vital. Regularly checking the calibration, lubrication, and overall condition of your machine can significantly reduce downtime and increase longevity. A well-maintained machine performs tasks with greater accuracy and requires fewer repairs, ultimately saving costs. Furthermore, utilizing advanced software for tooling setups can streamline operations. As highlighted in an industry study by Grand View Research, automated processes can enhance efficiency by up to 30%.

Secondly, utilizing quality materials tailored to your machine specifications not only improves the end product but also enhances cutting performance. High-quality end mills and substrates can significantly impact the machining process, providing smoother finishes and reducing wear. Remember to regularly evaluate and update your tool inventory to align with the latest advancements in the field. By adopting these strategies, users can ensure their CNC operations run smoothly and effectively in 2023.

Common Mistakes to Avoid When Using Table Top CNC Machines

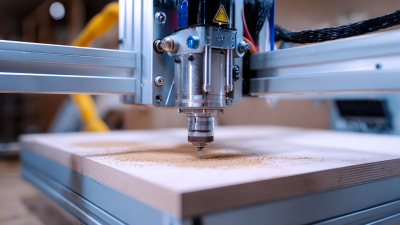

When using table top CNC machines, avoiding common mistakes can significantly enhance your precision engineering projects. One frequent error is neglecting the importance of proper setup. A misaligned workpiece can lead to inaccuracies that are difficult to rectify later. It is crucial to ensure that both the machine and the material are securely set up before beginning any operation. Taking the time to measure and calibrate correctly can save considerable time and resources.

Another mistake to avoid is underestimating the parameters of your cutting tools. Many users may select tools based on convenience rather than suitability for the project. Using the wrong feed rates or spindle speeds can not only lead to poor quality cuts but can also damage the machine itself. To achieve optimal results, it's essential to understand the specific requirements of the materials you are working with and to adjust your machinery accordingly. Continuous learning and adapting to the unique characteristics of your tools and materials will yield better outcomes and maintain the longevity of your CNC machine.

Maintenance and Care Tips for Longevity in CNC Equipment

Maintaining CNC machines is crucial for achieving precision in engineering, especially as industries increasingly rely on advanced technologies. Regular maintenance not only ensures operational efficiency but also significantly extends the lifespan of these machines. According to industry reports, planned maintenance can result in a reduction of equipment downtime by up to 30%, which emphasizes the importance of proactive care. Implementing predictive maintenance strategies can give machine operators insights into the health of their equipment, allowing for timely interventions before small issues escalate into costly repairs.

One effective approach to maintenance is leveraging advanced analytics tools that monitor machine performance in real-time. These tools can analyze various metrics, including vibration, temperature, and operational cycles, to predict potential failures. Studies have shown that companies utilizing predictive maintenance can experience a maintenance cost reduction of around 20% to 25%. By adopting such strategies, CNC machine users can ensure high levels of precision and reliability while maximizing their return on investment. Regularly scheduled inspections, cleaning, and lubrication also play critical roles in reducing wear and tear, thereby maintaining the integrity of these precision-engineered tools.

Top 5 CNC Machines Specifications and Maintenance Tips

This chart showcases the precision specifications (in micrometers) of the top 5 tabletop CNC machines for precision engineering in 2023. Regular maintenance and care can help achieve the best performance and longevity of these machines.

Related Posts

-

Top Strategies for Maximizing Efficiency with Desktop CNC Mills in Modern Manufacturing

-

Unlocking the Advantages of Table Top CNC Machines for Your Business Success

-

Versatile Applications of the Best Home CNC Machine in Diverse Industries

-

Navigating Global Trade Standards for Best Desktop CNC Machine Import and Export

-

7 Essential Tips for Maximizing Precision with Your Home CNC Machine

-

Maximize Your Investment with 7 Essential After Sales Tips for Best CNC Wood Cutting Machines

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information