Unlocking the Advantages of Table Top CNC Machines for Your Business Success

In today's fast-paced manufacturing landscape, the quest for precision, efficiency, and scalability drives businesses to explore innovative solutions. One such solution gaining traction is the table top CNC machine, a compact yet powerful tool that can transform the way companies approach their production processes. These machines offer a host of advantages, including reduced footprint, affordability, and versatility, making them ideal for small to medium-sized enterprises looking to enhance their capabilities without overwhelming their resources.

As we delve into the comprehensive checklist of benefits associated with table top CNC machines, you'll discover how harnessing this technology can lead to significant improvements in productivity, quality, and overall business success. Join us as we unlock the potential of these remarkable machines and explore how they can be a game-changer in your operations.

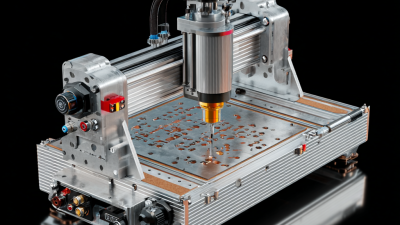

The Emergence of Table Top CNC Machines in Modern Manufacturing

The emergence of table top CNC machines marks a transformative step in modern manufacturing, significantly impacting productivity across diverse industries. Recent studies indicate that the utilization of CNC technology can enhance production efficiency by up to 30%, allowing businesses to streamline operations, reduce waste, and maintain high precision. As companies embrace digital manufacturing, table top CNC machines have gained traction for their space-saving designs and affordability, making advanced manufacturing capabilities accessible even to small and medium-sized enterprises.

In regions like Sriperumbudur, the adoption of these technologies is evident as businesses seek to improve their operational performance. This area, known for its robust industrial ecosystem, has seen an influx of startups harnessing CNC technology to innovate and compete in the market. With a growing trend towards automation and advanced manufacturing solutions, the demand for table top CNC machines is expected to rise, aligning with predictions for significant shifts in manufacturing processes leading into 2024 and beyond. As industries pivot to these machines, the landscape of manufacturing is on the brink of a significant evolution, driving both efficiency and success.

Comparative Analysis: Table Top CNC Machines vs. Traditional CNC Systems

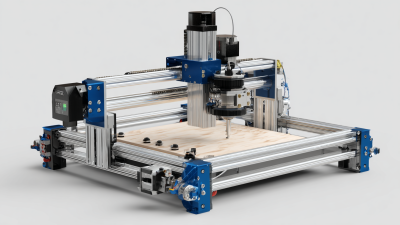

When considering the best machining solution for your business, a comparative analysis between table top CNC machines and traditional CNC systems can unveil significant advantages. Table top CNC machines are designed to be compact and user-friendly, making them ideal for small workshops or businesses that have limited space. They often come equipped with advanced features such as digital controls and automated functions that enhance precision and efficiency. Traditional CNC systems, while powerful and capable of handling larger projects, can be cost-prohibitive and require significant floor space, which may not be feasible for every operation.

In terms of versatility, table top CNC machines offer a unique edge. They can efficiently process various materials—from plastics to softer metals—allowing businesses to expand their service offerings without a considerable investment in additional machinery. The learning curve for operating these machines is also typically shorter, enabling businesses to train employees swiftly and reduce downtime. Traditional systems, in contrast, generally require specialized skills and ongoing maintenance to keep them operational, which can add to labor costs over time. Therefore, for many businesses, especially startups or those looking to optimize their workflow, table top CNC machines present a compelling alternative to traditional systems.

Cost-Benefit Metrics: ROI of Implementing Table Top CNC Technology

Table top CNC machines present a compelling case for businesses looking to enhance their operational efficiency and product quality. When examining the cost-benefit metrics, the return on investment (ROI) becomes clear. These machines not only reduce labor costs but also minimize material waste through precision machining. This heightened accuracy leads to fewer errors, resulting in significant savings over time. Businesses can expect a quicker turnaround on projects, allowing them to take on more jobs and increase overall revenue.

Tips for maximizing ROI with table top CNC technology include regular maintenance to ensure optimal performance, which can extend the lifespan of the equipment. Additionally, investing in employee training on the CNC technology can enhance productivity, as skilled operators are key to unlocking the full potential of these machines. Lastly, evaluate your projects to identify the best fit for CNC machining; knowing which tasks benefit most from automation can optimize resource allocation and further amplify returns. Embracing these strategies can solidify your decision on implementing table top CNC machines as a cornerstone of your business success.

Enhancing Precision and Efficiency: Data on Production Outcomes

In today's competitive manufacturing landscape, the advantages of table top CNC machines are becoming increasingly apparent, particularly regarding enhanced precision and efficiency.

According to a 2021 report by the International Manufacturing Technology Show, businesses utilizing CNC technology have reported an average of

30% increase in production efficiency. This efficiency is primarily due to the machines' ability to perform complex tasks with minimal human intervention,

drastically reducing errors and waste.

Moreover, precision is a critical factor in production outcomes, and table top CNC machines excel in this area.

The Precision Metalforming Association highlights that CNC machines can achieve tolerances of ±0.001 inches, a remarkable feat that traditional machining processes struggle to match.

This level of accuracy not only leads to better product quality but also directly impacts customer satisfaction and retention rates.

Businesses adopting these machines can significantly decrease their turnaround times while maintaining high-precision standards, ultimately driving profitability and success in a demanding market.

Moreover, precision is a critical factor in production outcomes, and table top CNC machines excel in this area.

The Precision Metalforming Association highlights that CNC machines can achieve tolerances of ±0.001 inches, a remarkable feat that traditional machining processes struggle to match.

This level of accuracy not only leads to better product quality but also directly impacts customer satisfaction and retention rates.

Businesses adopting these machines can significantly decrease their turnaround times while maintaining high-precision standards, ultimately driving profitability and success in a demanding market.

Case Studies: Successful Business Transformations Using Table Top CNCs

Table top CNC machines have transformed the way businesses operate, providing unparalleled precision and efficiency for various applications. In recent case studies, companies in industries from custom fabrication to artistic production have reported significant advancements after integrating CNC technology into their operations. For instance, a small furniture maker utilized a table top CNC to streamline their production line, allowing them to reduce waste and increase output. This transformation resulted in 30% higher productivity and the ability to meet growing customer demands.

When adopting table top CNC machines, businesses should consider a few key tips. First, investing in proper training for your team is crucial. Ensuring that operators are well-versed with the machine's functionalities can drastically reduce errors and enhance output quality. Additionally, maintaining a well-organized workspace will optimize both efficiency and safety, allowing for a smoother workflow. Another tip is to start with smaller projects to familiarize your team with the machine and gradually expand to more complex designs as skill levels improve.

Another case study highlights a jewelry business that switched to table top CNC machines for intricate design work. This transition allowed them to create highly detailed and customized pieces, resulting in increased customer satisfaction and loyalty. By adapting to technology, they could also reduce production costs, proving that innovation can directly impact a business's bottom line.

Related Posts

-

Versatile Applications of the Best Home CNC Machine in Diverse Industries

-

Top Strategies for Maximizing Efficiency with Desktop CNC Mills in Modern Manufacturing

-

Ultimate Guide to Choosing the Best CNC Engraving Machine for Your Business Needs

-

Exploring the Top Alternatives to Best CNC Router Machine for Your Manufacturing Needs

-

Discover the Finest Portable CNC Machines from China's Leading Manufacturers

-

The Future of Precision Crafting: Revolutionizing Wood Carving with the Best Wood Carving Machines

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information