Unlocking the Secrets of CNC Engravers Five Essential Tips for Optimal Performance and Precision

In the world of modern manufacturing and personalization, CNC engravers have emerged as indispensable tools for artists, craftsmen, and industrial creators alike. These sophisticated machines enable users to carve intricate designs with unparalleled precision and efficiency, transforming ideas into tangible masterpieces. However, achieving optimal performance with a CNC engraver requires more than just operating the machine; it demands an understanding of its capabilities, techniques, and maintenance practices. In this blog, we will unlock the secrets of CNC engravers by presenting five essential tips that will help you enhance both performance and precision. Whether you are a seasoned professional or a novice enthusiast, these insights will empower you to make the most of your CNC engraving projects, ensuring the highest quality results that reflect your creative vision. Join us as we delve into the best practices that will elevate your CNC engraving experience to the next level.

Understanding the Fundamentals of CNC Engraving for Better Results

CNC engraving is a fascinating fusion of technology and artistry, offering unlimited potential for creating intricate designs with consistent precision. Understanding the fundamentals of CNC engraving is essential for achieving optimal results. At its core, CNC (Computer Numerical Control) engraving involves the use of computer-driven machines to carve designs into various materials. A solid grasp of how to set up your machine, select the right tools, and configure parameters like speed and feed rates can dramatically affect the quality of your output.

CNC engraving is a fascinating fusion of technology and artistry, offering unlimited potential for creating intricate designs with consistent precision. Understanding the fundamentals of CNC engraving is essential for achieving optimal results. At its core, CNC (Computer Numerical Control) engraving involves the use of computer-driven machines to carve designs into various materials. A solid grasp of how to set up your machine, select the right tools, and configure parameters like speed and feed rates can dramatically affect the quality of your output.

One of the key aspects to focus on is the choice of materials and bits. Different materials, from wood to metal, require specific engraver bits designed for their properties. Additionally, familiarizing yourself with software that drives the CNC machine is crucial. Knowledge of design software and how to prepare files for engraving can streamline the process, ensuring that the final product aligns with your initial vision. With the right foundational knowledge, you can enhance both the efficiency and creativity in your CNC engraving projects.

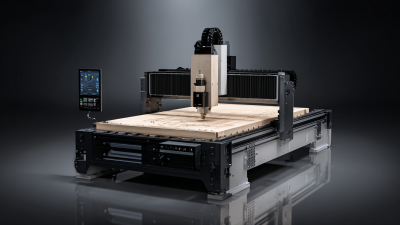

Choosing the Right CNC Engraver: Key Features to Consider

When selecting the right CNC engraver, it’s crucial to consider several key features that will directly impact your engraving projects. First and foremost, the type of material you plan to work with should determine your choice. Some CNC engravers are better suited for plastics, while others excel at wood, metal, or stone. Understanding your material will help narrow down your options and ensure compatibility.

Another vital aspect to contemplate is the size of the engraving area. Depending on the projects you intend to tackle, you may require a larger bed size for spacious designs. Additionally, consider the power of the spindle motor. A higher wattage can lead to faster engraving speeds and the ability to handle tougher materials, enhancing precision and efficiency.

Finally, always pay attention to the machine’s software capabilities. User-friendly software can significantly streamline your workflow and provide advanced features like 3D engraving and intricate design manipulation. Look for an engraver that offers compatibility with popular design programs, making it easier to bring your ideas to life. By keeping these factors in mind, you can maximize the potential of your CNC engraver for optimal performance and precision.

Optimizing Material Selection for Enhanced Engraving Quality

Choosing the right material for CNC engraving is essential for achieving optimal performance and precision. Recent studies indicate that the material’s composition directly affects the engraving quality, with hardwoods such as maple and cherry offering superior results compared to softer woods. According to the Woodworking Institute, these denser materials enable sharper details and deeper engravings, while softer woods tend to produce rougher outcomes, compromising the final aesthetic.

In addition to wood selection, there's a growing trend in utilizing composite materials for CNC projects. Research published by the American Society of Mechanical Engineers highlights that using composite materials can enhance both durability and intricate design capabilities, making them an excellent choice for complex projects. For instance, combining various polymers in a single engraving task allows for more vibrant color contrasts and textures that traditional materials simply cannot achieve. Thus, understanding and optimizing material selection not only elevates the quality of engravings but also expands the creative horizons for artists and craftsmen alike.

Unlocking the Secrets of CNC Engravers: Five Essential Tips for Optimal Performance and Precision

| Material Type | Recommended Bit Type | Engraving Speed (mm/min) | Depth of Cut (mm) | Surface Finish Quality |

|---|---|---|---|---|

| Acrylic | V-Bit | 1500 | 1-2 | High |

| Wood | Flat End Mill | 1000 | 2-3 | Medium |

| Metal | Ball Nose End Mill | 600 | 0.5-1 | High |

| Glass | Diamond Tip | 800 | 1-2 | Excellent |

| Leather | Laser Engraving Bit | 1200 | 0.5-1 | Good |

Mastering Software Settings: How to Fine-Tune Your CNC Engraver

Fine-tuning your CNC engraver's software settings is essential for achieving optimal performance and precision. Understanding the capabilities of the software you are using, whether it’s a dedicated program or open-source firmware, allows for more precise control and effective adjustments for various materials. For example, popular software like GRBL is invaluable for Grbl-based machines, enabling users to easily configure speed, steps per millimeter, and acceleration settings tailored to specific tasks. Mastering these settings can significantly enhance engraving quality and reduce trial and error.

Additionally, reviewing and utilizing recent advancements in CNC engraver technology can provide insights into how to improve your engraving process. New models featuring upgraded components or user-friendly interfaces can simplify software interaction and settings adjustments. By leveraging the capabilities of both the hardware and the associated software, users can unlock new levels of detail and efficiency in their projects, whether they are etching delicate designs or cutting functional parts.

Maintenance Best Practices for Longevity and Precision in CNC Engraving

Proper maintenance of CNC engravers is crucial for ensuring longevity and precision in your engraving projects. Regular cleaning of the machine components, including the spindle, bed, and cooling system, helps to remove debris and dust that can interfere with performance. It is essential to establish a routine cleaning schedule, as a clean workspace not only extends the life of your CNC engraver but also enhances the quality of the engravings produced.

Moreover, monitoring and calibrating your CNC engraver frequently can significantly impact its efficiency. This includes checking the alignment of the machine and ensuring that the cutting tools are sharp and properly installed. Dull or misaligned tools can lead to inaccuracies in engraving, resulting in wasted materials and time.

Additionally, lubricating moving parts is vital to minimize friction and prevent wear, which contributes to consistent performance and precision over time. By implementing these maintenance best practices, you can unlock the full potential of your CNC engraver, ensuring it operates smoothly and efficiently for years to come.

Related Posts

-

Solutions for Enhancing Production Efficiency with the Best CNC Engravers in 2023

-

Unlocking Precision in Manufacturing with Best Desktop CNC Tutorials for Global Buyers

-

Ultimate Guide to Choosing the Best CNC Engraving Machine for Your Business Needs

-

Exploring the Future of Best CNC Wood Carving Machines Market Trends and How to Choose the Right One for 2025

-

Craftsmanship Meets Innovation: The Best Home CNC Machines from China for Global Solutions

-

The Ultimate Guide to Choosing the Right CNC Routers for Woodworking Projects

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information