Unlocking Creativity: How CNC Routers for Woodworking Transform Your Projects

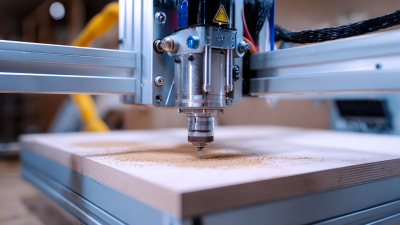

In the world of woodworking, innovation continually reshapes the landscape of creativity and craftsmanship. One of the most transformative technologies in this field is the advent of CNC routers for woodworking. These advanced machines harness the power of computer technology to execute intricate designs and patterns with unparalleled precision, allowing woodworkers to unlock new levels of creativity in their projects. As the demand for personalized and unique items increases, CNC routers have become essential tools for both amateur hobbyists and professional artisans.

CNC routers for woodworking not only streamline the production process but also open doors to endless possibilities in design. From detailed carvings to complex inlays, the versatility that these machines offer empowers woodworkers to envision and produce projects that were once deemed too challenging or time-consuming. By bridging the gap between traditional techniques and modern technology, CNC routers are revolutionizing how woodworkers approach their craft, leading to innovative designs that showcase individual creativity and style. As we delve deeper into the impact of CNC routers on woodworking, it becomes clear that these machines are not just tools; they are catalysts for creative expression.

Understanding CNC Routers: Essential Features for Woodworking Success

CNC routers have revolutionized the woodworking industry, enhancing the design process and production efficiency. Understanding the essential features of CNC routers is crucial for achieving woodworking success. Key aspects include precision, versatility, and ease of use. High-quality CNC routers provide consistent results, allowing woodworkers to create intricate designs with minimal effort. The ability to work with various materials, from softwoods to hardwoods and composites, ensures that users can tackle a wide range of projects.

Tip: When selecting a CNC router, consider the cutting area and the types of projects you plan to undertake. A larger cutting area enables bigger projects, but it’s also vital to ensure the machine fits comfortably in your workspace.

Moreover, modern CNC routers come equipped with advanced software that simplifies the design process. Features such as 3D modeling and digital templates can significantly reduce the time required for project planning. By leveraging these tools, woodworkers can focus more on creativity and less on manual fabrication.

Tip: Invest time in learning the software that accompanies your CNC router. Familiarizing yourself with its features can unlock new design possibilities and streamline your workflow.

Choosing the Right CNC Router: Key Considerations for Your Needs

When it comes to selecting the right CNC router for woodworking, there are several key considerations to keep in mind. First, assess your specific project needs. Different CNC routers come with varying cutting depths, material compatibilities, and bed sizes. If you plan to work on larger projects, a router with a bigger work area will be essential. Always match the router's capabilities to the type of woodworking tasks you intend to undertake, whether it's intricate designs or large-scale pieces.

Another important factor is the software compatibility of the CNC router. Make sure the router you choose can easily integrate with the design software you are comfortable using. Some routers come with proprietary software that might not be user-friendly or capable of supporting advanced designs. Evaluating the learning curve associated with the software can save you time and frustration later on.

Tips:

1. Research user reviews and testimonials to gauge the reliability and performance of different models before making a purchase.

2. Consider investing in a router that offers a strong support network or community, as this can be invaluable when troubleshooting or learning new techniques.

3. Don't overlook the importance of a sturdy workstation; a stable environment is crucial for achieving precise cuts and maintaining the integrity of your projects.

Setting Up Your CNC Router: A Step-by-Step Guide for Beginners

Setting up your CNC router can seem daunting, especially for beginners who are eager to dive into woodworking projects. The initial phase involves selecting the right CNC router that suits your needs, whether you want a compact model for simple tasks or a more advanced version for intricate designs. Once you have your router, ensure that it is placed on a sturdy, stable surface to prevent any vibrations that could affect the precision of your cuts.

Next, it's crucial to understand the software that will drive your CNC router. Familiarizing yourself with design software that can create vector files is essential. These files guide the router in executing your projects. After setting up the software, calibrate the router by checking its dimensions and adjusting the settings to match your desired materials and projects. This meticulous setup process will pave the way for smoother operations and unlock the true potential of your woodworking creativity. Armed with the right tools and knowledge, you will be well on your way to transforming your ideas into stunning wooden creations.

Unlocking Creativity: CNC Routers in Woodworking Projects

This bar chart illustrates the time saved in hours when using CNC routers for various woodworking projects. The data showcases how effective CNC technology can be in enhancing productivity and creativity in woodworking.

Designing Projects for CNC Routing: Tips and Techniques for Creative Freedom

When designing projects for CNC routing, creativity knows no bounds. The key is to start with a clear vision of what you want to create. Begin by sketching your ideas on paper or using design software to visualize your project. This planning phase allows you to experiment with different shapes, patterns, and dimensions, ensuring that your final design not only meets your aesthetic requirements but also suits the capabilities of your CNC router. Remember to consider the type of wood you are using, as different materials can yield different finishes and textures.

Incorporating innovative techniques can further enhance your creative freedom. For instance, using layers in your design allows for intricate patterns and a three-dimensional effect that adds depth to your project. Additionally, familiarity with the CNC router's software and settings can enable you to experiment with various cutting speeds and bit types, leading to unique finishes and details. Don't be afraid to push boundaries—combine traditional woodworking techniques with modern CNC routing methods to create a truly one-of-a-kind piece that reflects your personal style and imagination.

Troubleshooting Common CNC Routing Issues: Ensuring Smooth Operation

When utilizing CNC routers for woodworking projects, encountering issues is a common challenge that can disrupt the creative process. One of the most frequent problems is improper tool calibration, which can lead to inaccurate cuts. To troubleshoot this, start by checking the alignment of the router and the workpiece. Regularly inspect the tool’s sharpness and ensure that it is securely mounted. Keeping the machine clean and free from debris can also help maintain precision and prevent errors during operation.

Another common issue arises from software errors, particularly when transferring designs to the CNC machine. Ensuring that the file format is compatible and that the software settings match the router's specifications can help reduce such problems. Additionally, maintaining an updated version of your CNC routing software can enhance performance and introduce new features that improve workflow. By anticipating these common pitfalls and implementing proactive maintenance strategies, woodworkers can ensure smoother operations and achieve their creative visions with confidence.

Related Posts

-

Exploring the Unique Features and Applications of Various CNC Router Machine Alternatives

-

Exploring the Versatility of CNC Routers: Innovations in Crafting and Manufacturing

-

Exploring the Future of Best CNC Wood Carving Machines Market Trends and How to Choose the Right One for 2025

-

Exploring Examples of the Best CNC Wood Router Machines for Global Buyers

-

The Ultimate Guide to Choosing the Right CNC Routers for Woodworking Projects

-

7 Essential Tips for Maximizing Precision with Your Home CNC Machine

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: sale@atmmachinesolutions.com

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information