DeskProto

DeskProto CAM Software

DeskProto is an NC programming system (CAM)

for automatically generating 3D CNC codes for CNC machines.

Available in 3 versions: Entry, Expert & Multiaxis.

from 172,55 €

(incl. German VAT)

System requirements

To run Deskproto you need a PC with the following requirements:

- Windows operating system

- CPU: Minimum 1GHz (recommended 2Ghz)

- RAM: Minimum 512 MB

- Grafic: Standard graphic card

- Connections: LPT (printer port) and / or USB

- Hard disk with enough free memory

- keyboard

- mouse

- monitor

was designed to create CNC programs quickly and easily using 3D geometry.

Particular care was taken to ensure that even CNC beginners quickly achieve decent and high-quality results with the program.

The software is designed almost exclusively for the 3D area. Rapid-Prototyping on CNC machines speeds up the development and design process, as it quickly gives a “tangible” result.

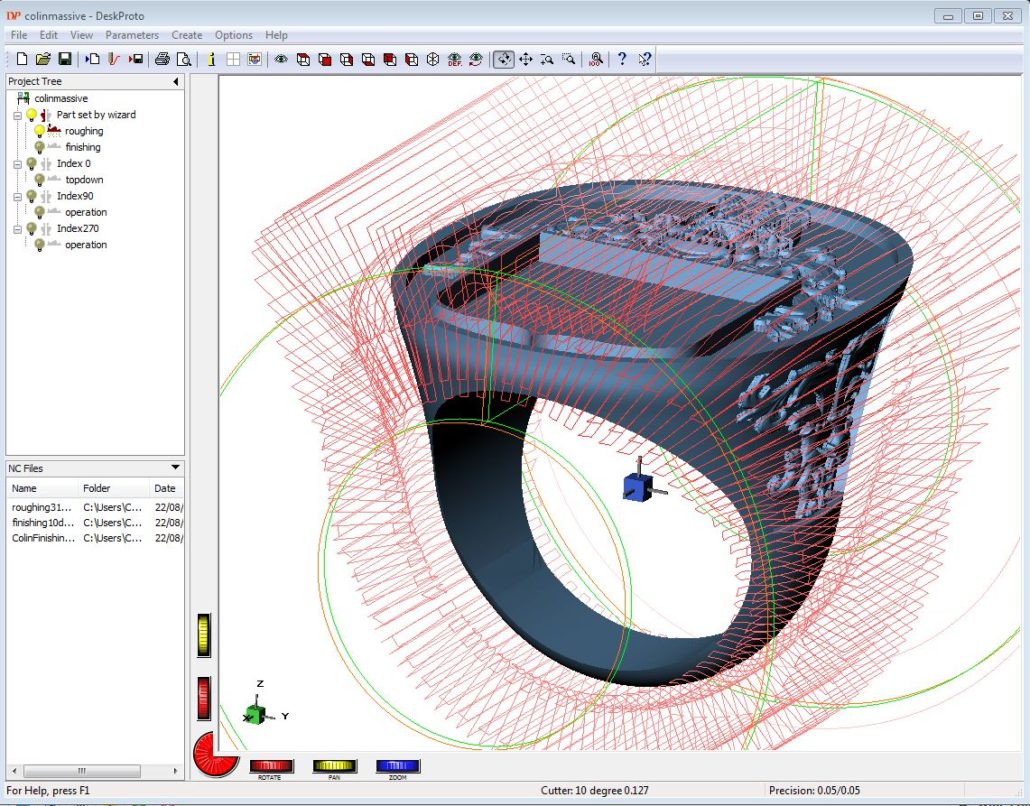

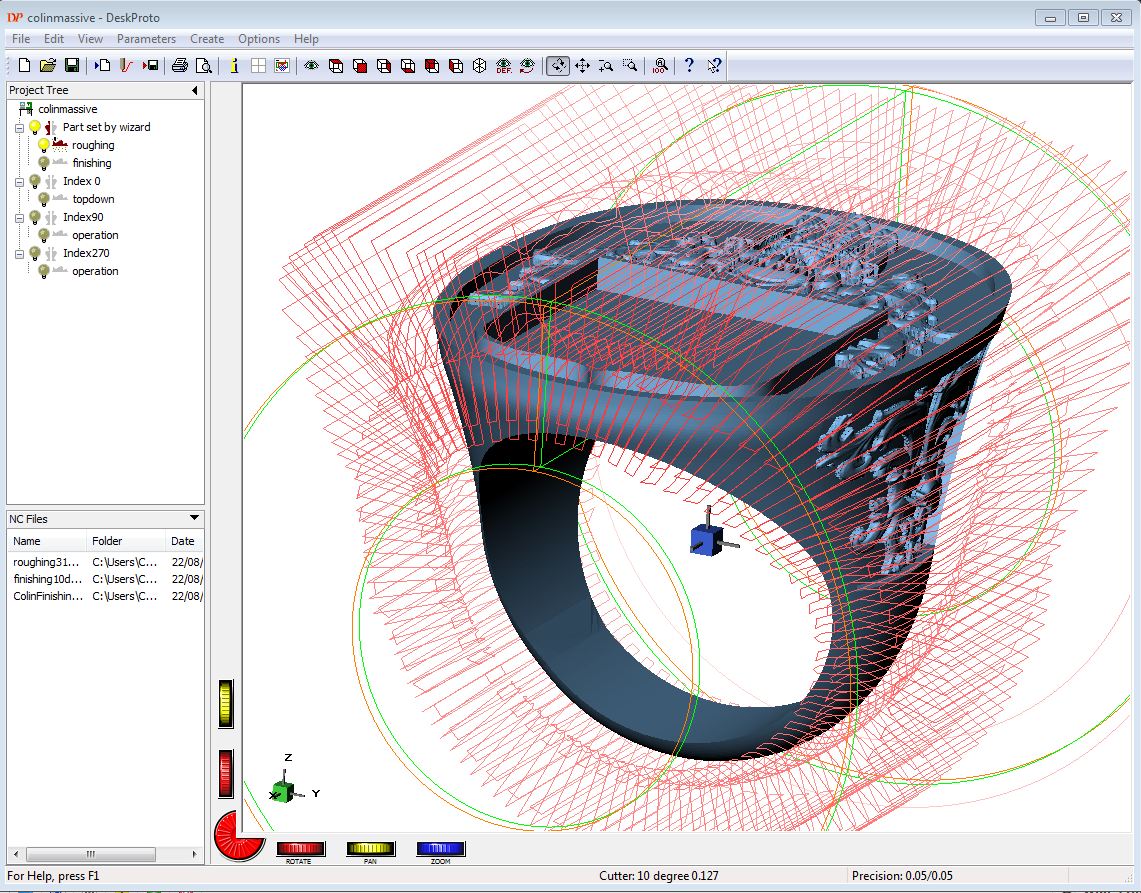

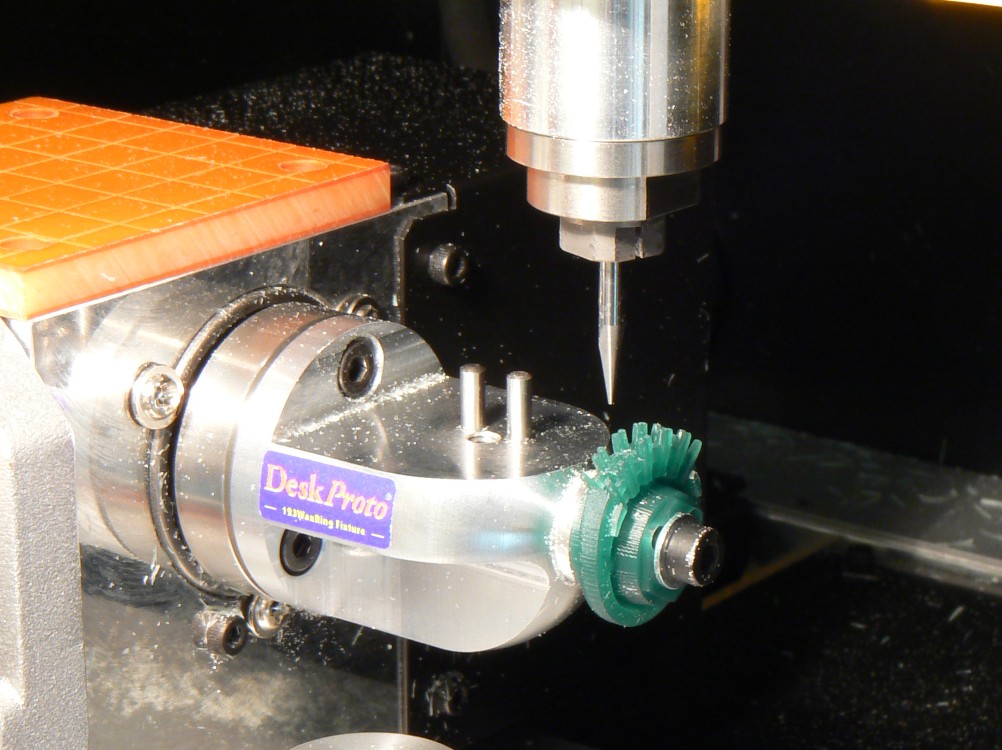

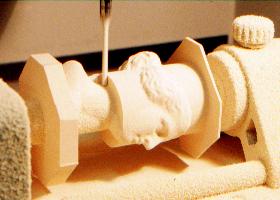

DeskProto needs only a 3D model to create the CNC programs. Programs are generated for 3-axis machines, optionally also with rotary axis (see picture), ie on 4-axis CNC machines. Standard projects can be saved within the processing and used so quickly for new projects.

DeskProto is very inexpensive. An easy handling, a short learning process and a small price distinguish this software especially.

DeskProto Version overview

DeskProto Entry

In the ENTRY Edition, the CAM program provides the most important parameters for creating the G-code for 3D models and simple 2D milling. Also, the 3D milling of a bitmap file is supported.

DeskProto Expert

The EXPERT Edition has the complete DeskProto functionality for 3D CAM programming for CNC machines with three simultaneous axes.

DeskProto Multi-Axis

In addition to three and four-axis (4-channel or 5-channel) machines, the MULTI-AXIS Edition also supports 5-axis CNC machines with a pivotable rotary axis for 3D CAM programming.

| Functional Comparison | ENTRY Edition |

EXPERT Edition |

Multi-AXIS Edition |

|---|---|---|---|

| CAD-Import | |||

| 3D Import (STL, VRML, meshed DXF) | √ | √ | √ |

| 2D Import /DXF, EPS, AI) | √ | √ | √ |

| Bitmap Import (jpg, gif, bmp) | √ | √ | √ |

| For machines with: | |||

| 3 Axes | √ | √ | √ |

| 4 Axes (3 Axes + rotation axis) | √ | ||

| 4 Axes (3 Axes +Index axis) | √ | ||

| 5.Axis (manual) | √ | ||

| Strategies | |||

| roughing | √ | √ | √ |

| Parallel to the X-axis | √ | √ | √ |

| Crosswise, block, Z-constant, 3D contour outside | √ | √ | |

| Circular or spiral milling | √ | √ | |

| Meander, synchronism, counter milling | √ | √ | |

| Project 2D geometry onto 3D model | √ | √ | |

| Automatic, dynamic feed adjustment with large removal |

√ | √ | |

| Patial processing | |||

| define processing spaces (segments) | √ | √ | |

| Define freeform segments | √ | √ | |

| interleave free-form segments | √ | √ | |

| Milling only model | √ | √ | |

| Postprocessor | |||

| many already exist | √ | √ | √ |

| User configurable | √ | √ | √ |

| Scripts (wizards) |

|||

| various standard scripts | √ | √ | |

| own scripts | √ | √ | |

| 123WaxRing Assistant | √ | ||

| Others | |||

| Show undercuts | √ | √ | |

| 3D simulation | √ | √ | √ |

| inverse processing | √ | √ | |

| Two sides machining (assistant) | √ | √ | |

| automatically install webs | √ | √ | |

| Tool holder collision check | √ | √ | |

| Convert bitmap to 3D | √ | √ | √ |

| Project bitmap onto 3D models | √ | √ | |

And that’s how easy it is (video):

It’s so easy to work with our machines! Design your drawing or CAD data, e.g. in ConstruCAM-3D or Corel Draw and convert them into a G-code. The CNC machine is controlled by the CNC program Win-PC NC.